China Aluminum Product Source Factory

Large-volume Trading Offers Many Discounts

Aluminum Production Base

Dongchong is one of the most trusted aluminum plate manufacturers and source factories in China, with business all over the world. We specialize in providing aluminum sheets, aluminum coils, aluminum strips and aluminum foils to companies in various industries.

Main Business

Minimum Order Quantity (MOQ): 4000kg per size / thickness

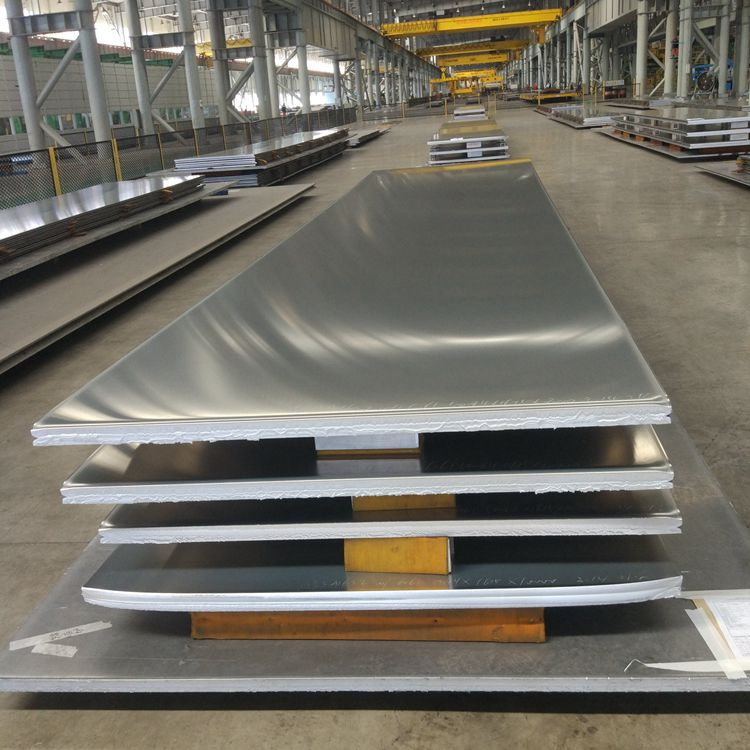

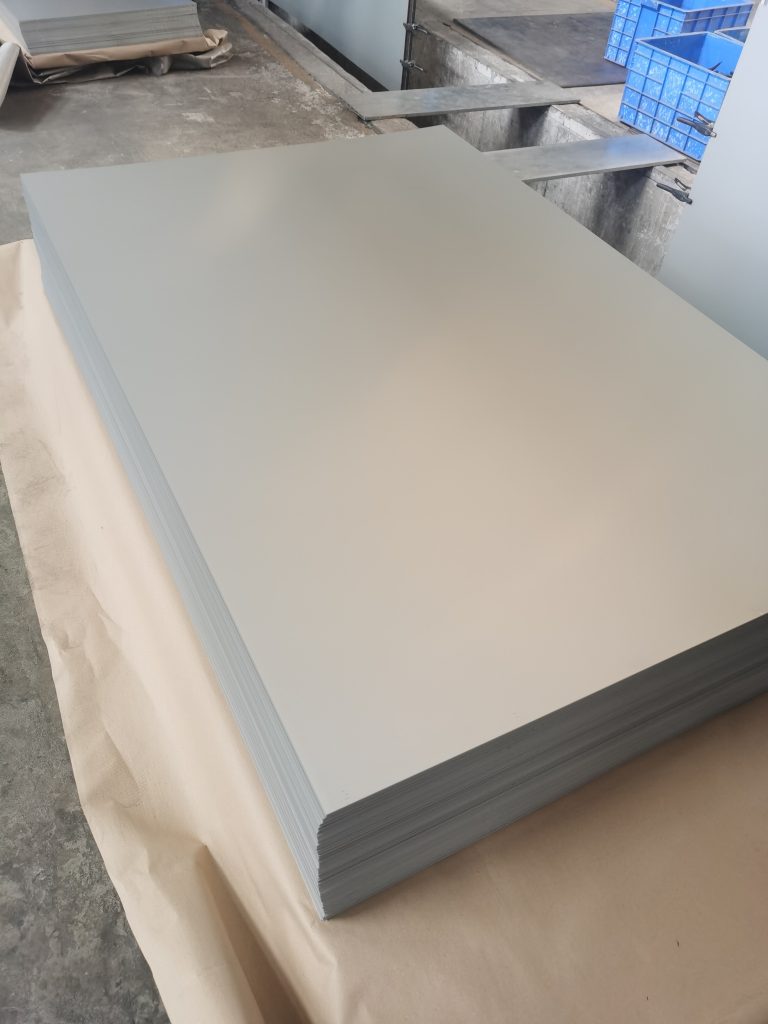

Aluminum Plate & Sheet

As a professional aluminum sheet manufacturer, we focus on providing high-quality aluminum sheets for various industrial fields, covering a wide range of application scenarios from basic building decoration to high-end electronic equipment manufacturing, and are committed to meeting the diverse requirements of different customers in terms of aluminum sheet performance, specifications, and quality.

Checkered Aluminum Plate

As a leading source factory, we specialize in producing diverse Checkered Aluminum Plates. Our product range includes various types such as three – rib, five – rib, anti – slip, and perforated plates. The three – rib and five – rib checkered plates are ideal for vehicle flooring and walkways, providing excellent traction and durability. The anti – slip checkered plates are perfect for applications where safety is paramount, such as in wet or oily environments. Perforated checkered plates are widely used in architectural decorations and sound – absorption panels. We provide customized services to meet specific customer requirements.

Anodized Aluminum Plate

Our anodized aluminum sheets are carefully crafted from high-purity aluminum to ensure unmatched quality and performance. Whether you are looking for materials for architectural cladding, automotive components, consumer electronics, or other high-end applications, our anodized aluminum sheets are the perfect choice. They are designed to withstand harsh environmental conditions, ensuring long-lasting durability and minimizing maintenance. Work with us to experience the superior quality and reliability that only an experienced and professional aluminum sheet producer can provide.

Aluminum Round Rod

As a source manufacturer of aluminum bars, the aluminum bars we produce are made of strong and durable 6061-T6 aluminum alloy, ensuring that the products have excellent strength and are suitable for a variety of harsh applications. In addition, these products have excellent machinability and are easy to process with precision, which can meet the diverse needs of customers from all walks of life.

Aluminum Square Rod

At our aluminum profile manufacturing facility, we specialize in producing high-quality 6061 aluminum square bars. These extruded profiles feature a square cross-section, offering exceptional rigidity and structural stability. This material provides an excellent balance of strength and workability, making it ideal for various applications that require durable yet processable aluminum components.

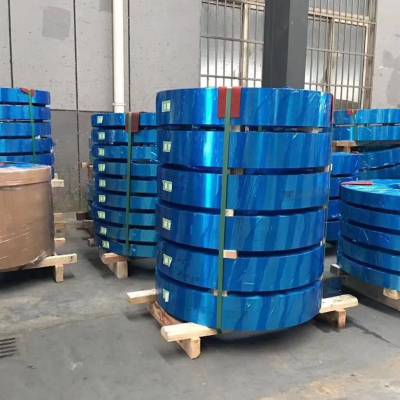

Aluminum Coil

As a leading source factory, we offer both conventional Aluminum Coils and the premium-colored Coated Aluminum Coils. Our Aluminum Coils, crafted from high – purity aluminum and various alloys, feature excellent durability, corrosion resistance, and thermal conductivity. They come in diverse thicknesses and widths, catering to construction, packaging, and appliance industries.

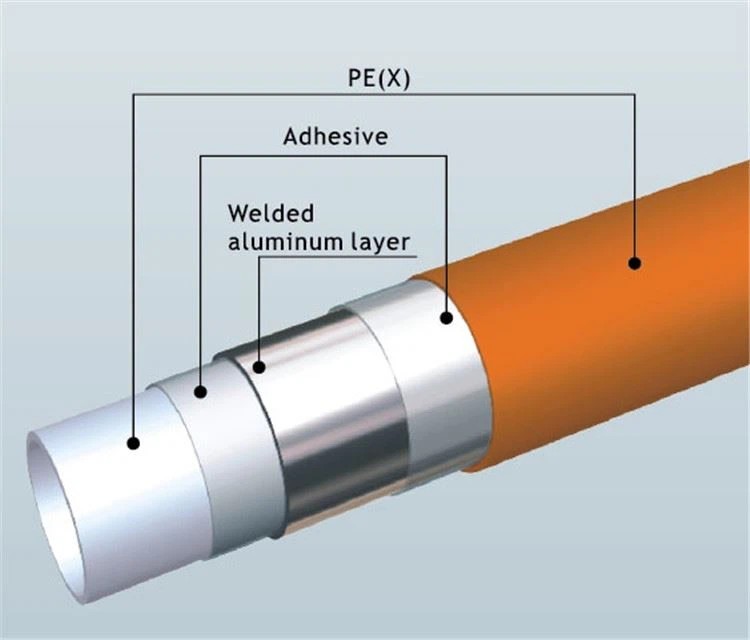

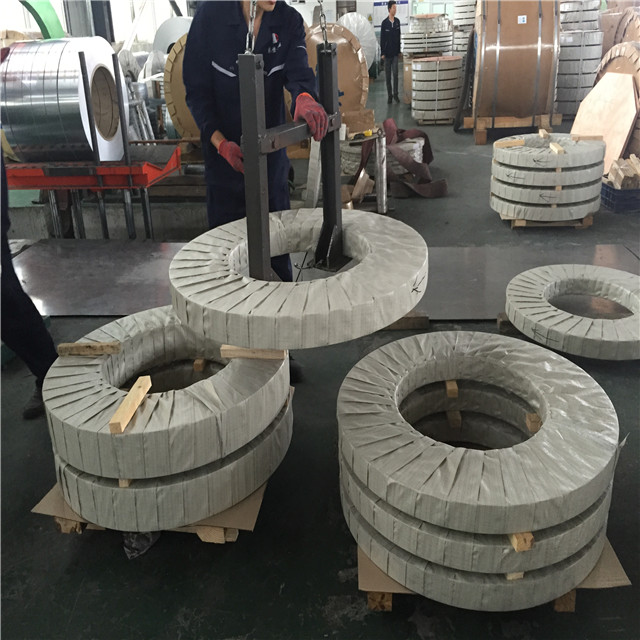

Aluminum Strip

As a top – tier source factory, we specialize in Aluminum Strip production. Our strips vary in thickness and width, made from high – purity aluminum and various alloys, featuring excellent strength, corrosion resistance, and thermal conductivity. Advanced equipment ensures precise dimensions and smooth surfaces, while strict quality checks guarantee reliability. Widely used in electronics, automotive, and construction, our Aluminum Strips meet diverse customer needs. We offer customized services and efficient logistics for timely, secure deliveries. Choose us for premium quality and competitive prices.

Factory & Production Line

Raw Material Warehousing Inspection

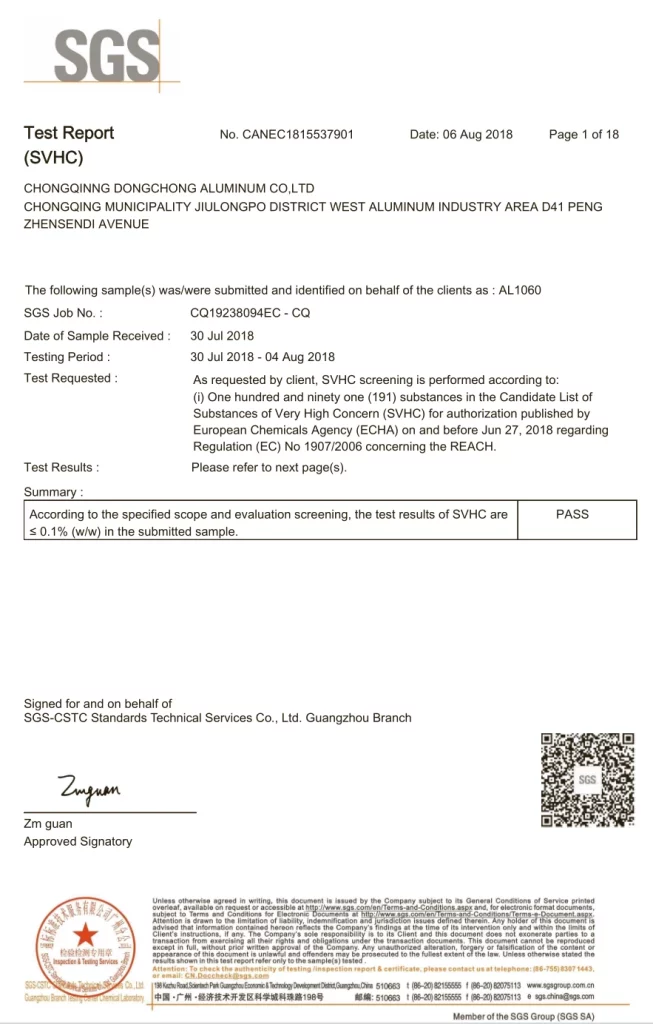

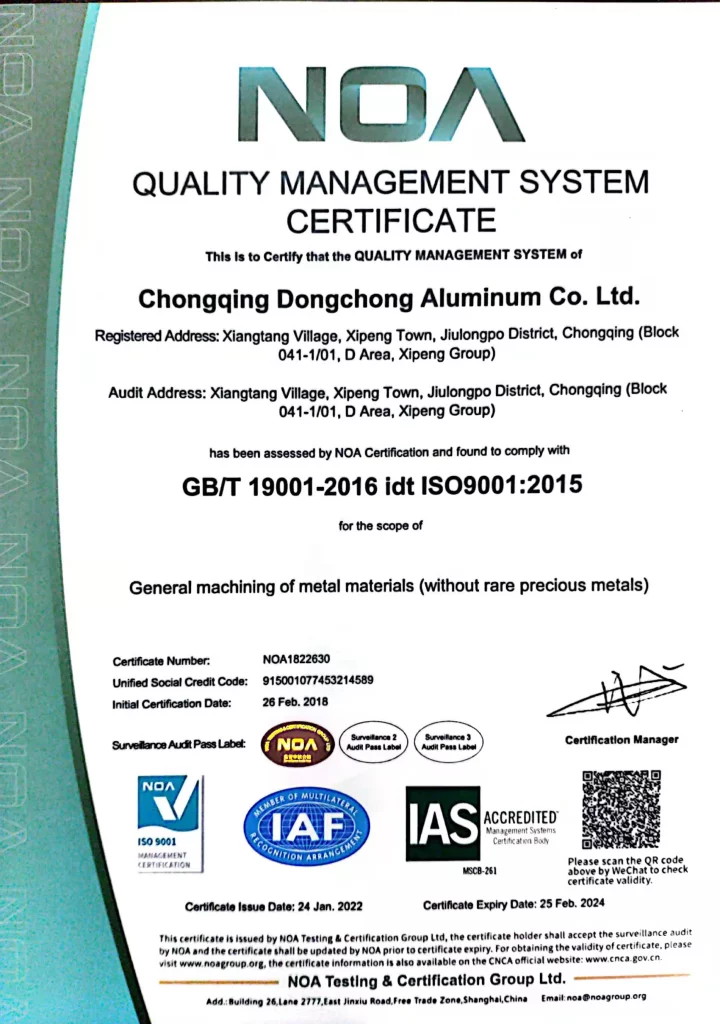

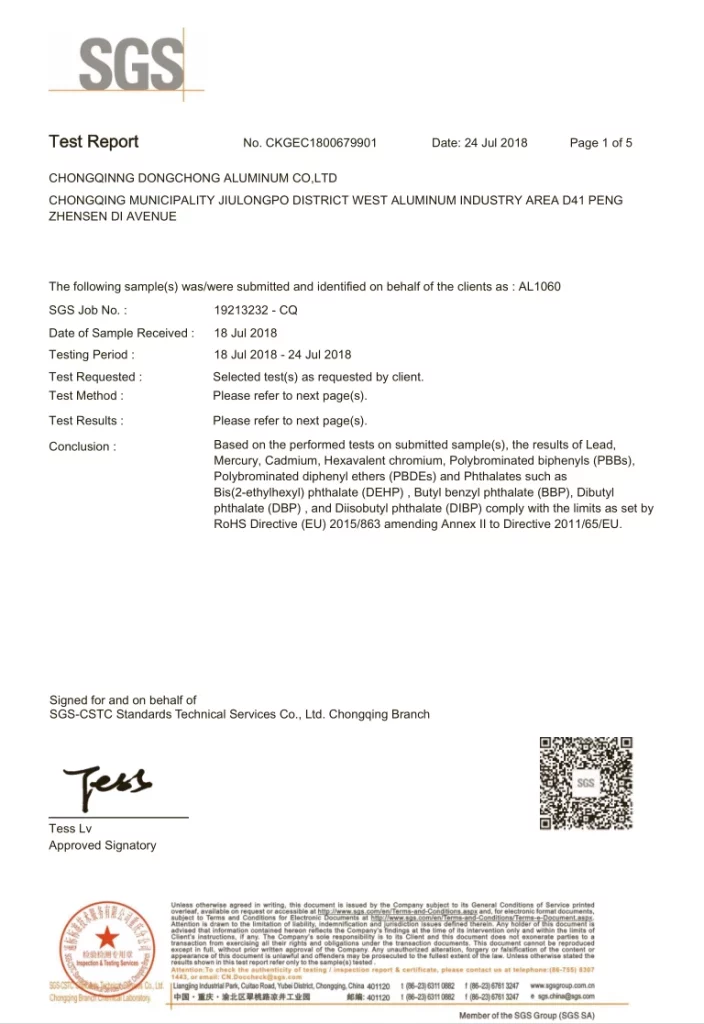

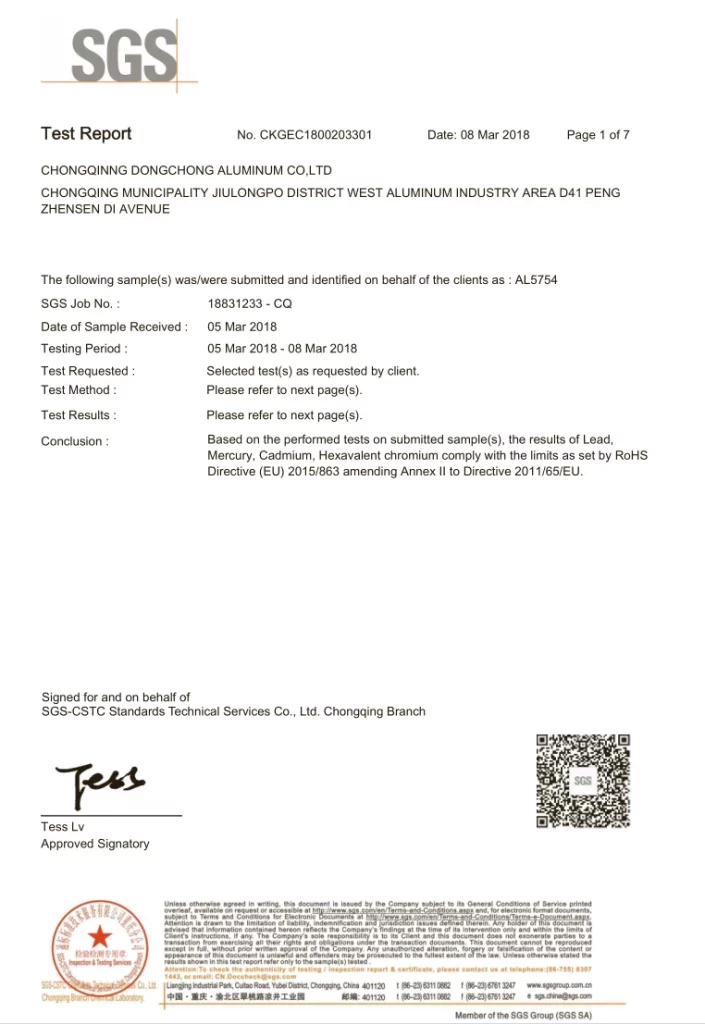

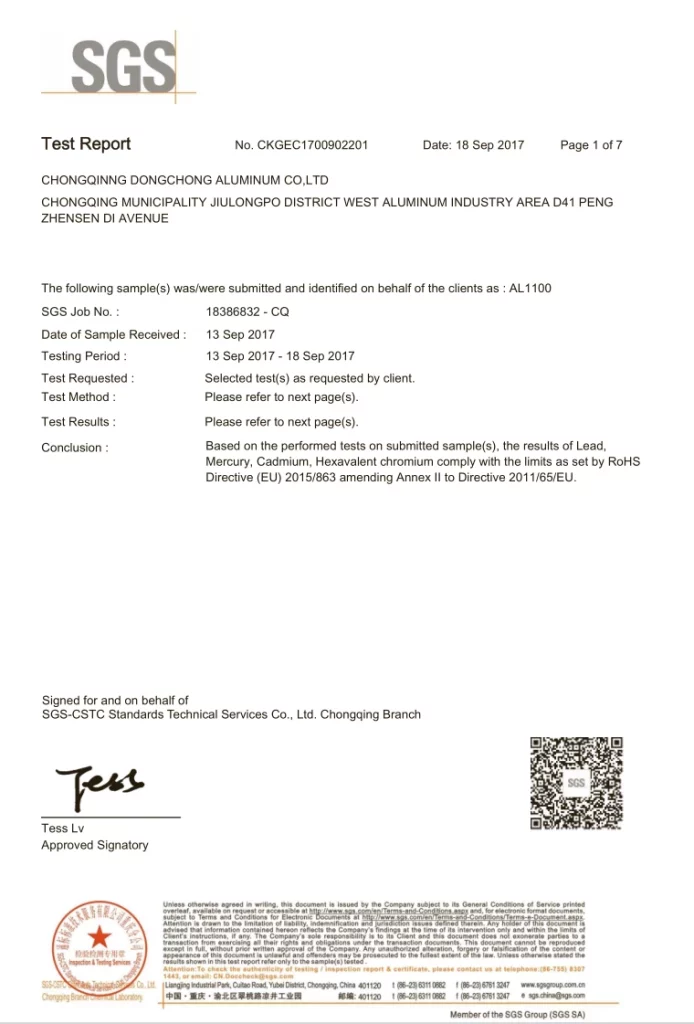

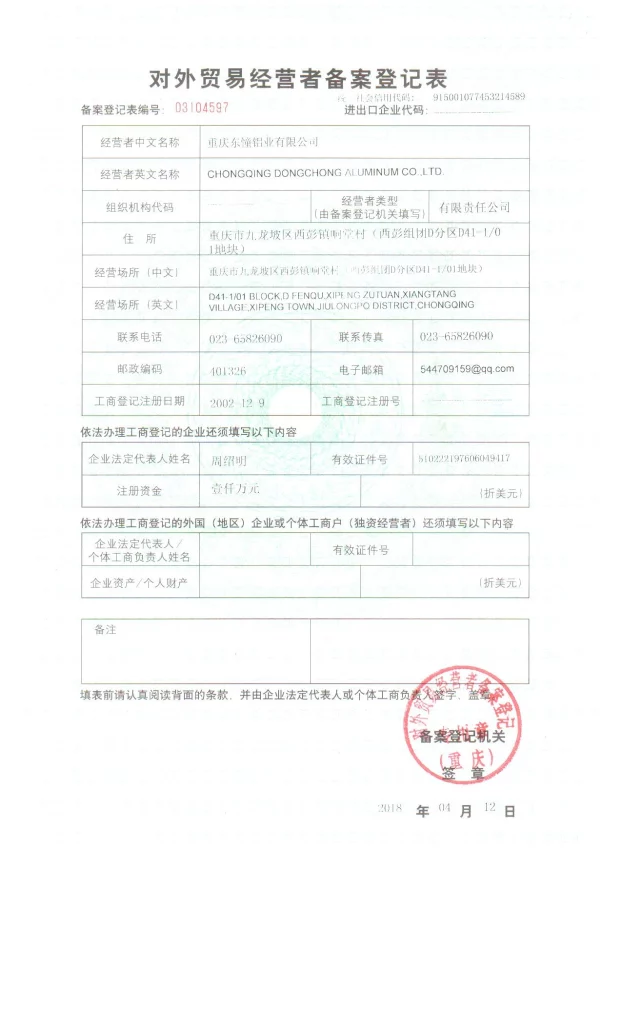

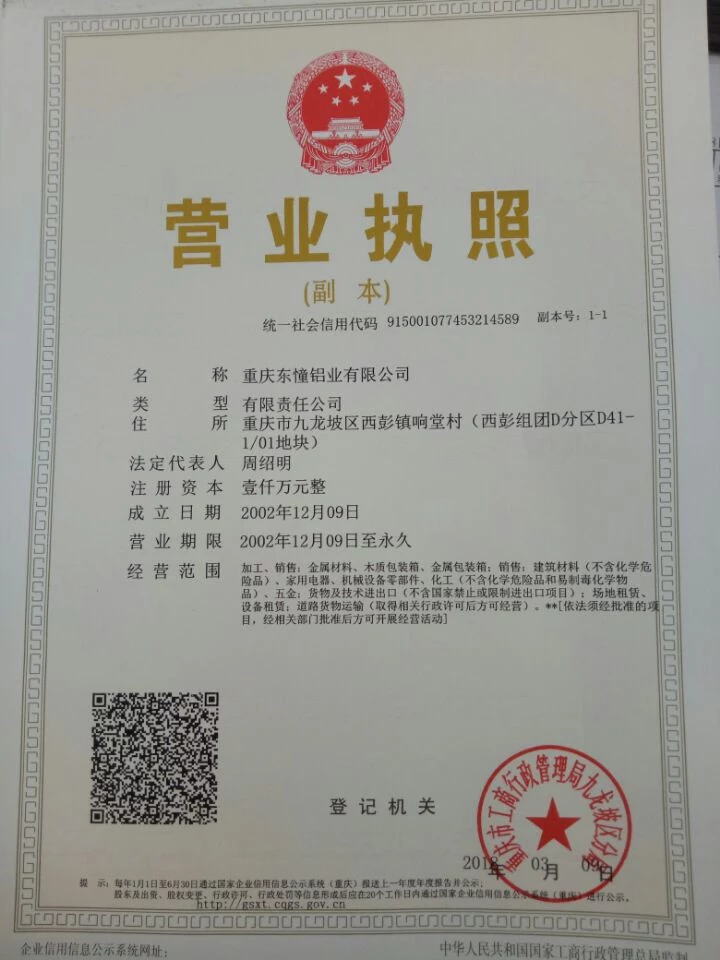

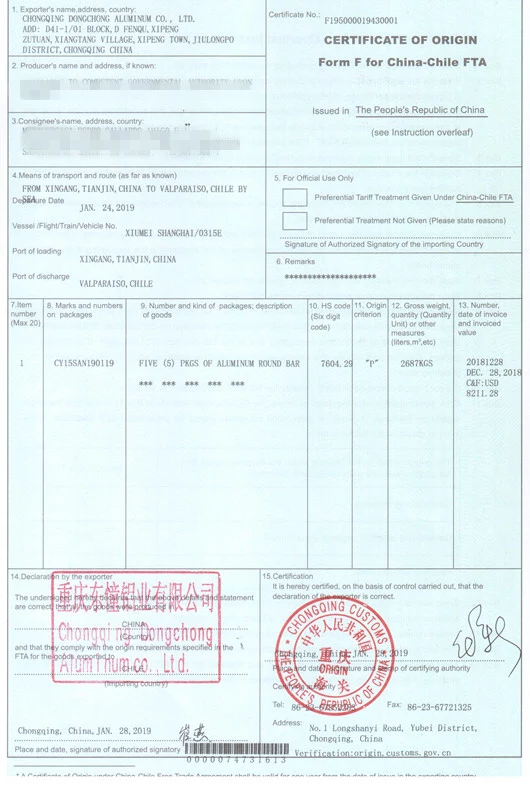

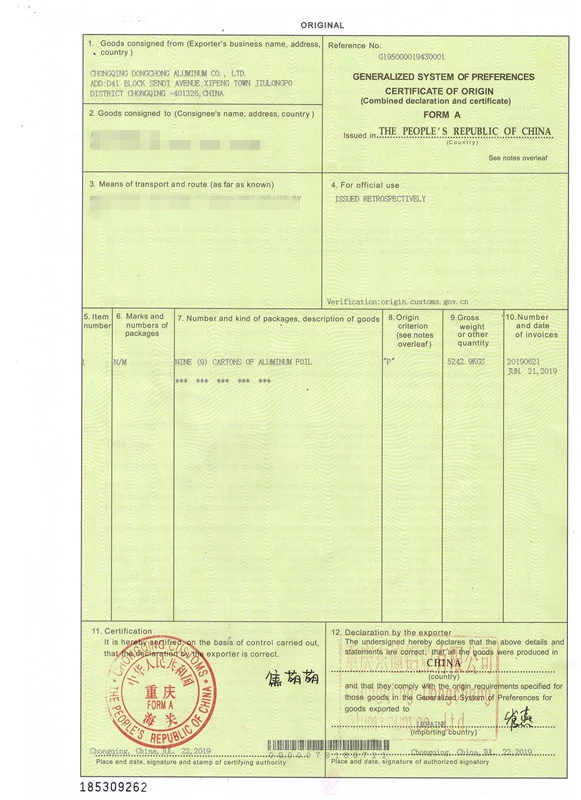

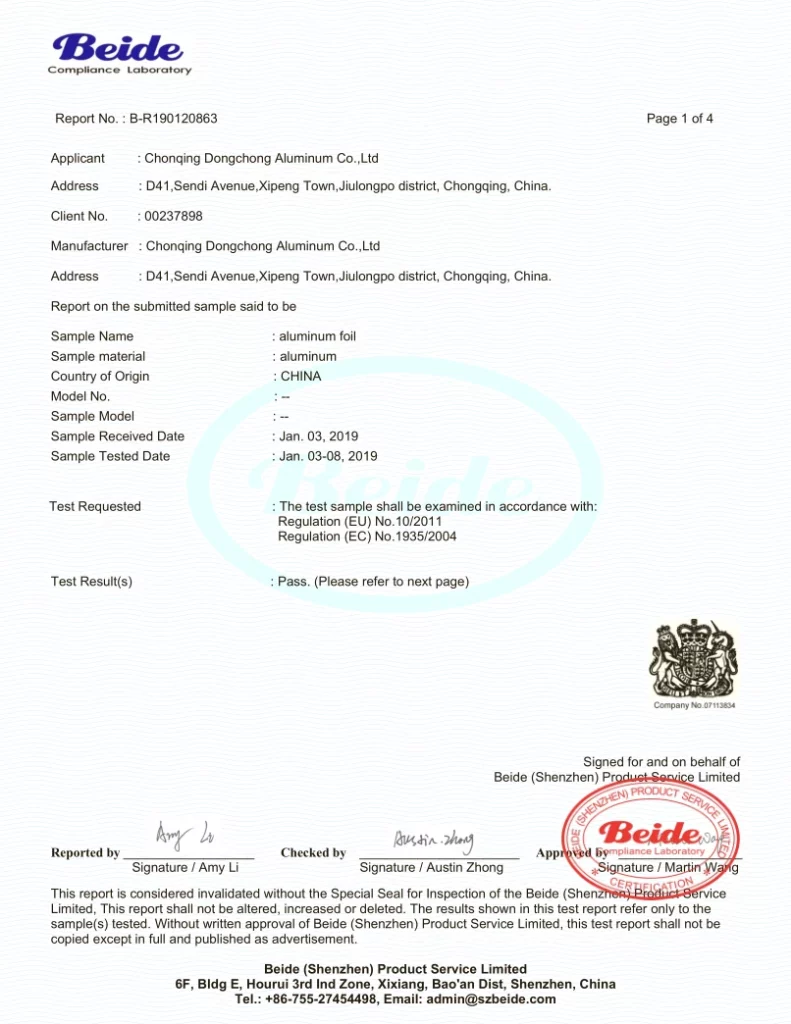

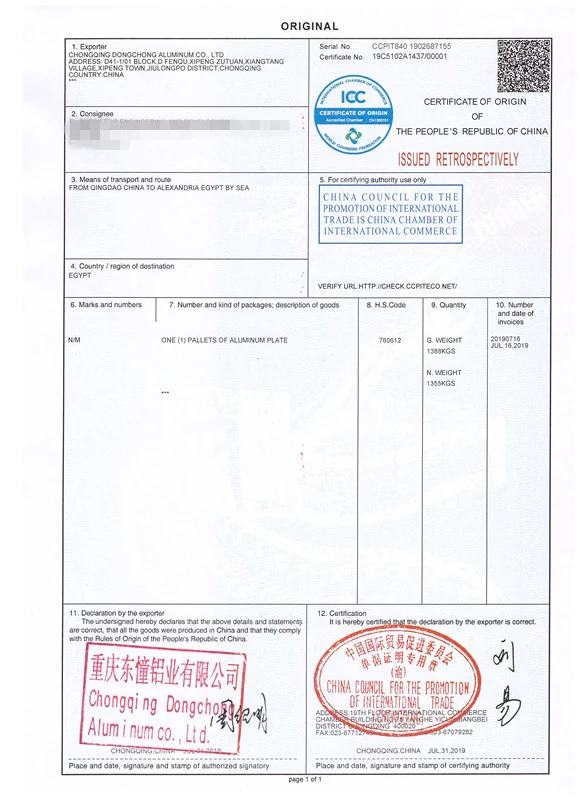

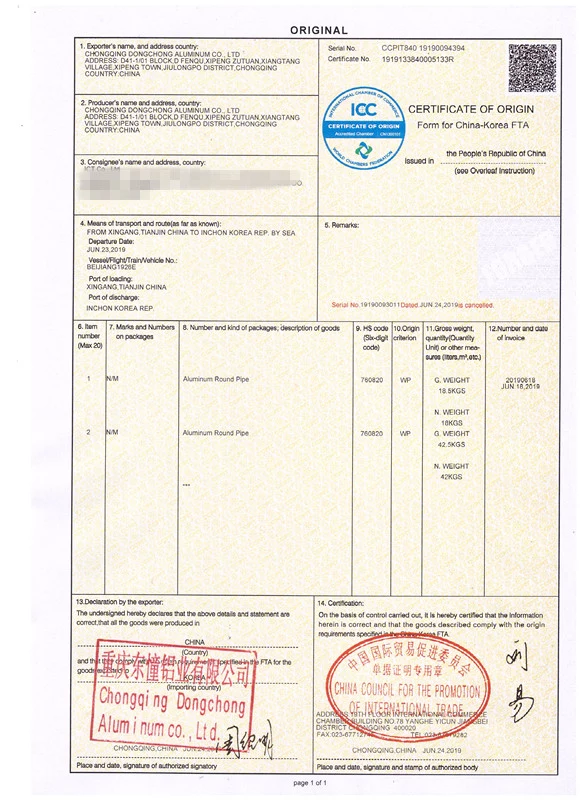

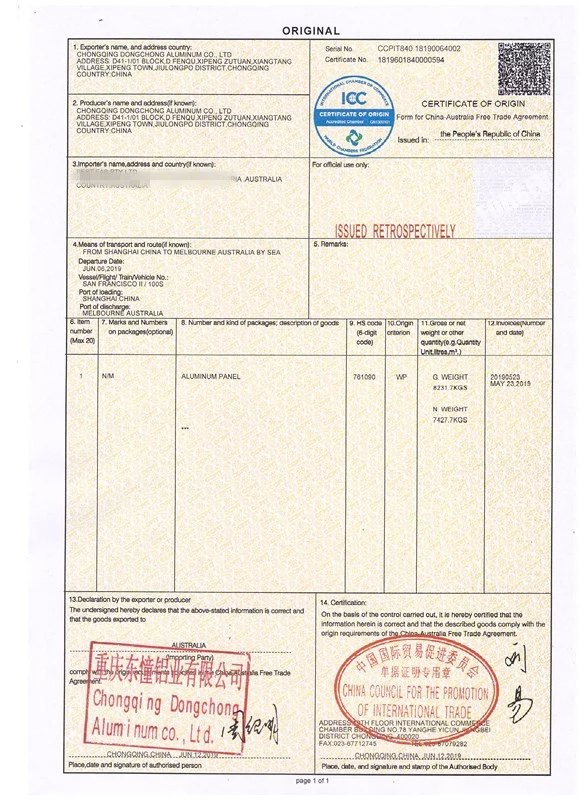

Certificates

Production Video

Product Packaging

Aluminum Plate Packaging

Aluminum Plate Packaging Aluminum Coil Packaging

Aluminum Coil Packaging Aluminum Strip Packaging

Aluminum Strip Packaging Wooden Pallet

Wooden Pallet Wooden Box

Wooden Box Container

Container

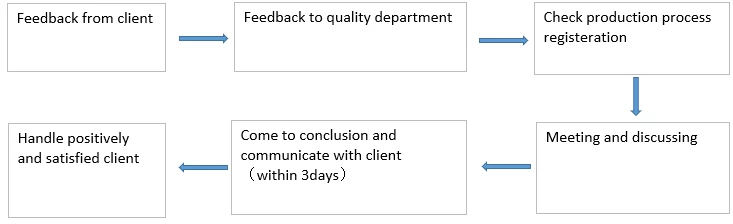

After-Sales Management

Why Choose Us

China’s Top 10 Aluminum Spot Centers

From standard alloys to custom solutions, we deliver consistency and reliability to meet the diverse demands of industries like automotive, construction, and packaging. Choose us for high-quality materials, flexible customization, and unwavering service. Partner with China’s leading aluminum supplier—where innovation meets excellence.

Stable and High-quality Inventory

The factory is located in Chongqing, China and is a giant in aluminum production. In terms of product output, we produce 500,000 tons of aluminum sheets and strips every year. In terms of market supply strategy, we always keep 10,000 tons in stock. This is not only to meet the daily needs of the domestic market, but also to ensure a stable supply in foreign markets.

Stable Supply Chain Management

Our efficient supply chain management optimizes logistics, reduces transportation costs and losses, and improves delivery efficiency. In addition, accurate demand forecasting and inventory management reduce inventory holding costs, avoid additional costs caused by out-of-stock or excess inventory, and thus significantly reduce overall costs.

Main Applications Scenarios

We focus on customized solutions and value-added services to meet the specific needs of our customers. We continuously strive to provide the highest quality products and services.

Factory Advantages

Strict Quality Control

Using advanced testing equipment and strict quality control system, each batch of aluminum plates is strictly tested to ensure that the products meet international and industry standards.

Fast Delivery

According to the customer’s urgency and order volume, we can flexibly adjust the production plan, give priority to urgent orders, and ensure that customers receive the products on time.

Wide Product Range

We have a rich series of aluminum plate products, covering standard plates, high-purity plates, alloy plates, color decorative plates, corrugated plates and perforated plates, which can meet a wide range of industrial and decorative needs.

Price Advantage

As a professional aluminum sheet manufacturer, we have large-scale production lines that enable efficient production, thereby reducing unit costs and providing customers with more competitive prices.

More Details About Each Aluminum Grade

| 1100 | 1100 is commercially “pure” aluminum. It’s 99% aluminum composition lends this grade soft and workable. It is also has high electrical and thermal conductivity and excellent resistance to corrosion. |

| 3003 | This manganese alloy shows an excellent combination of formability and corrosion resistance with good strength levels between the 1xxx and 5xxx series. |

| 3004 | Similar to 3003, this alloy shows good strength, corrosion resistance, and formability. It’s commonly purposed for beverage cans and non-structural automotive components. |

| 3105 | 3105 is a non-heat treatable alloy with good weldability that is frequently purposed in residential siding, trailers, and signage. |

| 5005 | This grade is excellent for decorative applications and can be easily anodized. It is not intended for applications where strength is critical. |

| 5049 | This magnesium alloy is similar to 5052 in that it has good corrosion resistance, weldability, and is easy to form though it has higher hardness. It is commonly seen in shipbuilding. |

| 5052 | This is a moderate strength alloy with good formability, weldability, and resistance to corrosion. In automotive applications, you’ll see it used in interior and exterior bracketry. It is also commonly used for kitchen equipment and bulk processing equipment. |

| 5083 | 5083 shows excellent resistance in seawater and other highly corrosive environments. Warm metal forming for complex automotive shapes and shipbuilding. |

| 5086 | This is a non-heat treatable alloy best suitable for marine environments. It shows good strength, weldability, machinability, and corrosion resistance. |

| 5182 | This is the most common of the 5xxx series alloys to be used for automotive structural applications. It has high strength and formability, and is also often seen in the construction industry. |

| 5251 | This grade is common in the food processing, automotive, and aviation industries. It has lower strength than some of the other 5xxx series alloys but shows high fatigue strength and is easy to weld. |

| 5754 | This is a common wrought alloy for structural automotive applications. It can be easily roll formed, extruded, and forged. |

| 6061 | 6061 is one of the most commonly extruded alloys. It has an excellent strength-to-weight ratio, machinability, weldability and can be anodized. |

| 6062 | 6062 aluminum alloy has high strength, corrosion resistance, good welding and processing properties, and is suitable for manufacturing parts with complex shapes. It is widely used in aerospace, automotive, marine and construction fields. |

| 6063 | 6063 is utilized across a range of industries for fabrication projects requiring good strength and corrosion resistance. It is one of the most popular alloys for extrusion. It is most ideal for architectural trim. |

| 6082 | This high strength, heat treatable, impact and corrosion resistant alloy primarily used for load bearing framework in automotive applications, cranes and bridges. |

| 6181 | This alloy has some of the best surface finishing characteristics. This, in addition to good strength, corrosion resistance, and good weldability makes it suitable for exterior automotive paneling. |

| 7075 | 7075 aluminum alloy has high strength, better mechanical properties than 6062, and moderate corrosion resistance, which can be improved through specific treatment, but poor weldability. It is often used in high-load structural parts in aerospace, military and other fields. |

| 8011 | 8011 aluminum alloy has high corrosion resistance, good ductility and high thermal conductivity, and is used in food and drug packaging and building insulation panels. |

Our Team

Contact Us

Professional services are just one step away! Click the form below to fill in your basic information and business needs, and you will receive exclusive services from our professional team. We promise to keep your information strictly confidential, handle every consultation efficiently, and make cooperation easier