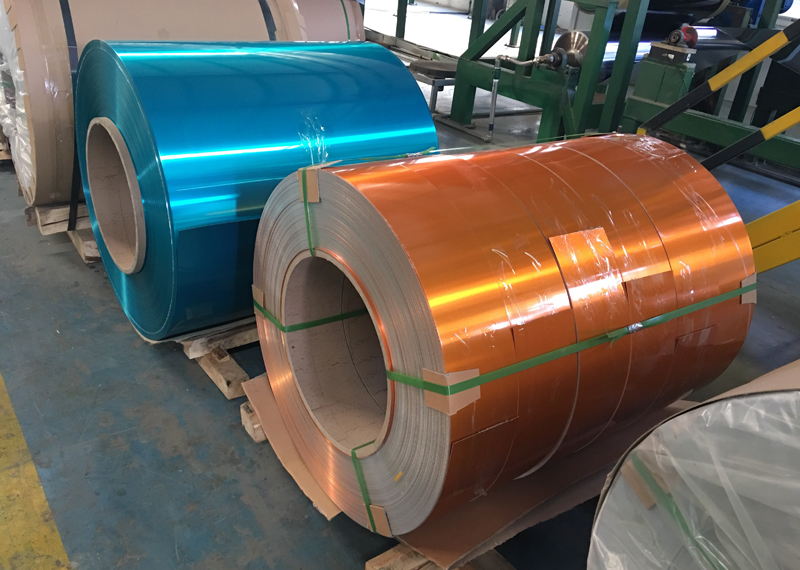

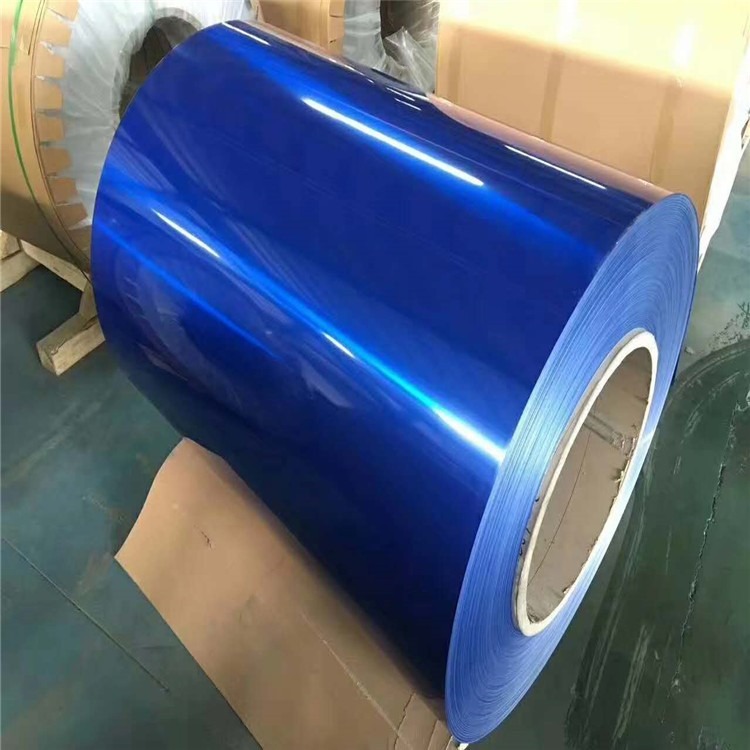

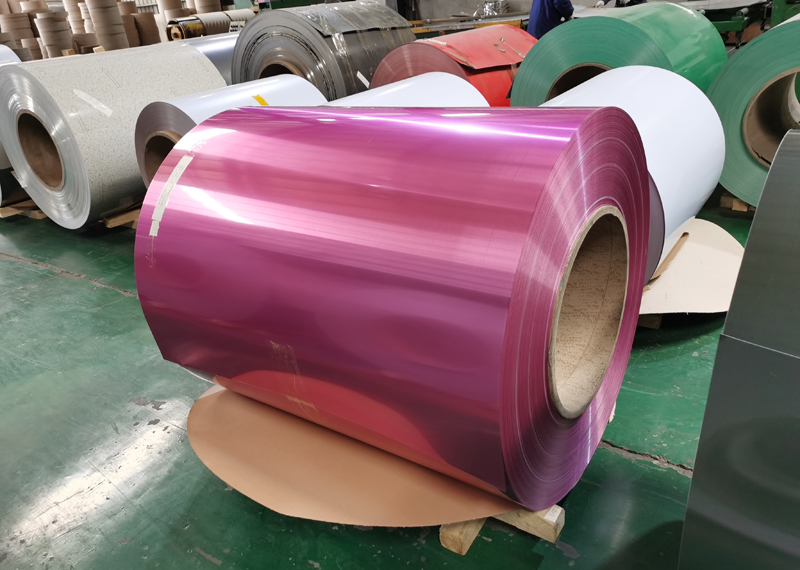

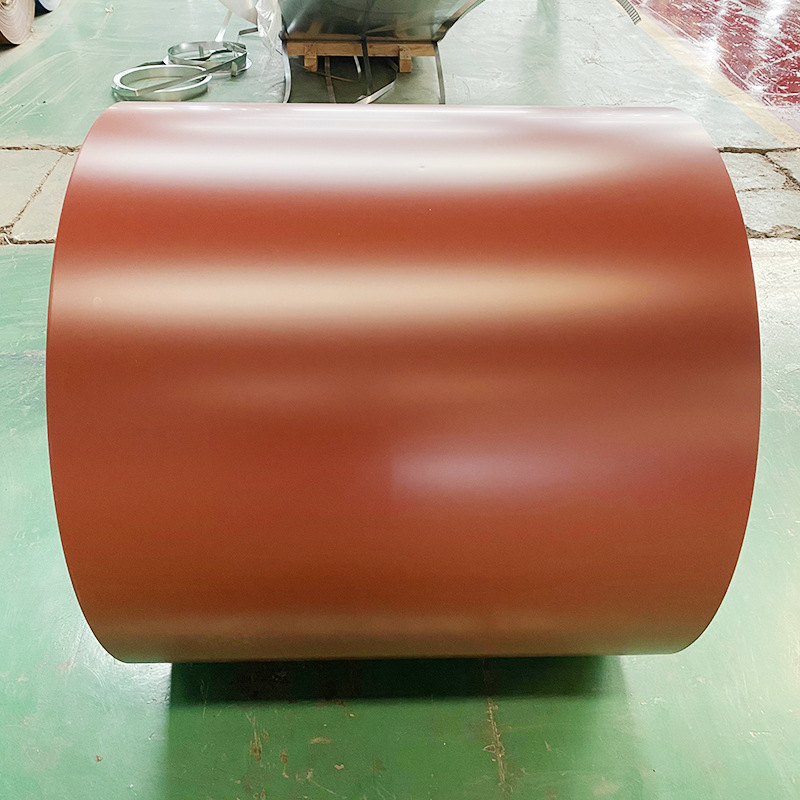

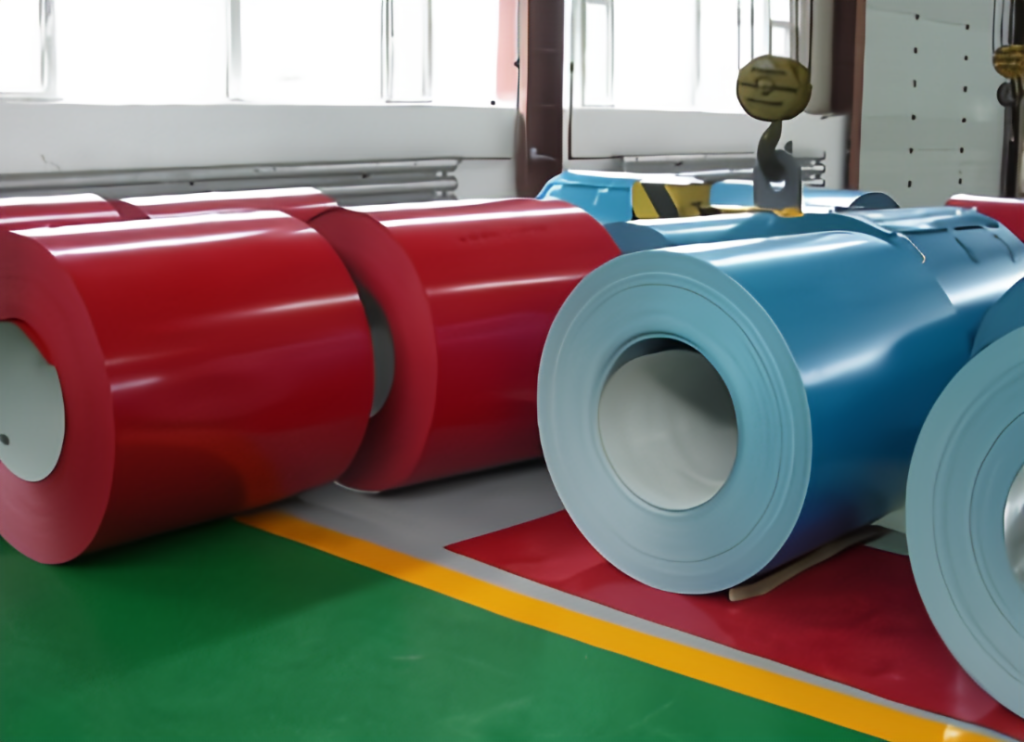

Colored Aluminum Coil

1050 Colored Aluminum Coil

Description Color coated aluminum coil is a product made by…

1060 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

1100 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

1070 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

3003 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

3004 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

3105 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

5052 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

5754 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

5083 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

6061 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…

6063 Colored Aluminum Coil

Description Color coated aluminum coils, processed through cleaning, chrome plating,…