6061 T6 Aluminum Rod

- Alloy: 6061

- Temper: T6 T651

- Diameter: 3 mm – 300 mm

- Production Method: Extruded

- Service: 7/24 work for you any time

- Packing: Strapping, Plastic bag, Film, Wooden pallet Standard seaworthy export packing or according to customer requirement

- MOQ: 4000kg per size / thickness

- Extrusion: Formed by pushing heated aluminum through a circular die.

- Cold Drawing: Optional process to achieve tighter tolerances and smoother surfaces.

- Machining: Easily drilled, turned, or milled into complex shapes.

Description

| Specification of 6061 Aluminum Rod

6061 aluminum rod is a versatile and widely used aluminum alloy product, renowned for its excellent balance of strength, corrosion resistance, and workability.

| Product | 6061 Aluminum Rod |

| Temper | T6 / T651 |

| Types | Round bars, square bars, hexagonal bars, angle bars, flat bars |

| Diameter | 3 mm – 300 mm |

| Common Standards | ASTM B211 (USA), EN 755-2 (Europe), JIS H4140 (Japan). |

| Common Standard Diameters | 6 mm, 10 mm, 12 mm, 16 mm, 20 mm, 25 mm, 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm, etc. |

| Length | 1000 mm – 6000 mm. Custom lengths can also be provided according to customer needs |

| Packing | Strapping, Plastic bag, Film, Wooden pallet Standard seaworthy export packing or according to customer requirement |

| Payment | T/T, L/C 100% at sight |

| Diameter Tolerance | Typically ±0.05 mm to ±0.2 mm (depending on size; tighter tolerances for precision applications). |

| Straightness | Usually ≤ 0.5 mm/m (can be improved via cold drawing) |

| MOQ | 4000kg per size / thickness |

| Delivery time | 1-3 days for spot goods, 10-15 days for normal size,15-25 days for special size. |

| Application | Construction, Shipbuilding, Decoration, Industry, Manufacturing, Machinery, Hardware and other fields |

| Chemical Composition of 6061 Aluminum Rod

6061 aluminum rod primarily consists of aluminum, with key alloying elements including magnesium (Mg) and silicon (Si). The typical chemical composition is as follows:

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al |

| 6061 | 0.40~0.8 | ≤0.7 | 0.15~0.40 | ≤0.15 | 0.8~1.2 | 0.04~0.35 | ≤0.25 | ≤0.15 | ≤0.15 | 97.8 – 98.8% |

| Physical Properties of 6061 Aluminum Rod

| Property | Value Range | Applications |

| Density | Approximately 2.7 g/cm³ | Aerospace and automotive industries where weight reduction is crucial. |

| Melting Point | 582 – 652 °C | Casting and forming processes. |

| Thermal Conductivity | 167 – 188 W/(m·K) | Heat sinks and applications requiring efficient heat dissipation. |

| Mechanical Properties of 6061 Aluminum Rod

| Property | Value Range | Description |

| Tensile Strength | 310 – 324 MPa | High strength suitable for structural applications. |

| Yield Strength | 276 – 290 MPa | Good resistance to deformation under load. |

| Elongation | 8 – 12% | Good ductility and ability to withstand plastic deformation without cracking. |

| Hardness | 65 – 95 HRB | Good level of wear resistance. |

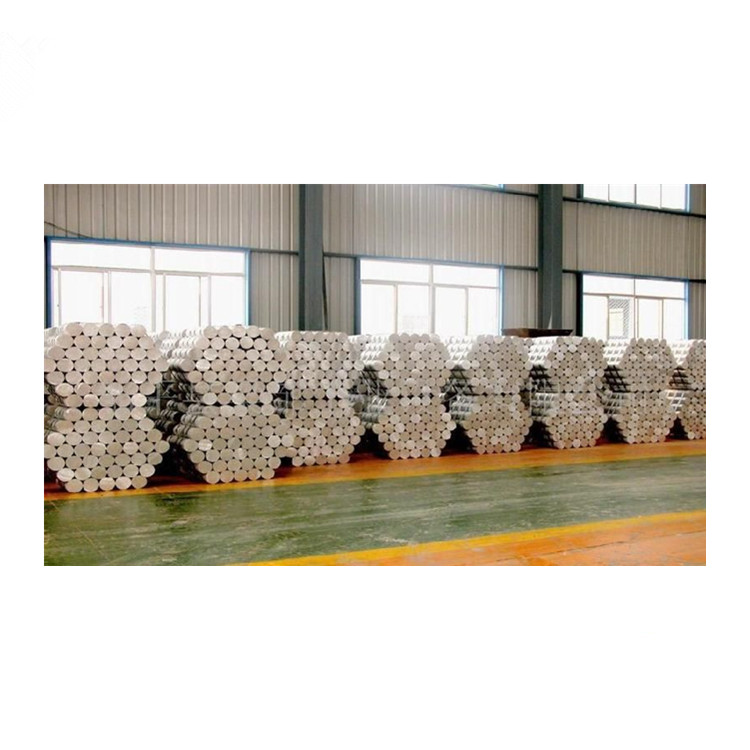

| Warehouse Display

| Applications of 6061 Aluminum Rods

6061 aluminum rods are highly versatile and widely utilized across diverse industries due to their exceptional balance of lightweight, strength, corrosion resistance, and machinability. Below are their key application fields:

Aerospace Industry

- Use Cases: Structural components (e.g., fuselage frames, wing supports), brackets, landing gear parts, and lightweight mechanical assemblies.

- Why It’s Ideal: Its high strength-to-weight ratio reduces aircraft weight while maintaining structural integrity, critical for fuel efficiency and performance.

- Typical Products: Aircraft interior/exterior parts, aerospace fasteners, and components requiring precision machining.

Automotive Industry

- Use Cases: Engine components (e.g., cylinder heads, pistons), suspension parts (e.g., control arms, steering knuckles), chassis frames, and heat sinks.

- Why It’s Ideal: Lightweight properties help reduce vehicle weight, improving fuel economy and performance. Corrosion resistance is also vital for underbody and exterior parts.

- Typical Products: Electric vehicle (EV) structural parts, automotive accessories, and high-performance racing components.

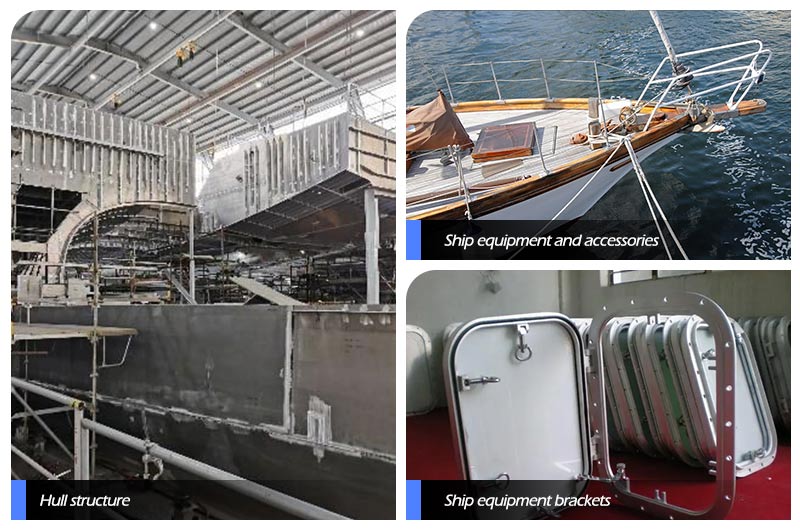

Marine Industry

- Use Cases: Boat hull components, deck fittings, propeller shafts, marine hardware (e.g., hinges, brackets), and offshore structural parts.

- Why It’s Ideal: Excellent corrosion resistance to saltwater ensures durability in marine environments. Lightweight design also enhances boat speed and fuel efficiency.

- Typical Products: Yacht components, fishing boat structures, and underwater equipment parts.

Industrial and Mechanical Engineering

- Use Cases: Machine shafts, gears, actuators, fixtures, and structural supports in manufacturing equipment.

- Why It’s Ideal: High tensile strength and machinability make it suitable for load-bearing components. Resistance to wear and tear ensures long service life in industrial applications.

- Typical Products: Conveyor system parts, robotic arm components, and heavy machinery fixtures.

Sports and Recreation

- Use Cases: Bicycle frames (especially for mountain bikes and road bikes), golf club shafts, hiking poles, kayak paddles, and ski equipment.

- Why It’s Ideal: Lightweight design enhances user comfort, while strength and durability meet the demands of high-impact sports.

- Typical Products: High-performance bicycle components, camping gear, and fitness equipment.

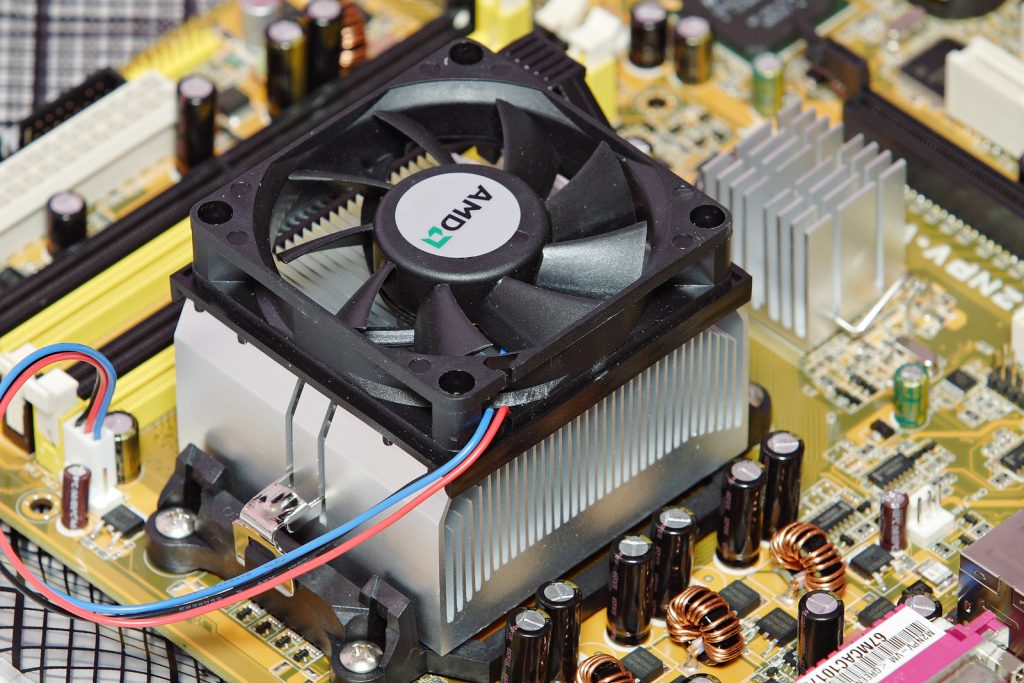

Electronics and Heat Management

- Use Cases: Heat sinks for electronic devices (e.g., computers, LED lights), radiator components, and thermal management systems.

- Why It’s Ideal: Good thermal conductivity allows efficient heat dissipation, preventing overheating in sensitive electronics.

- Typical Products: Computer CPU coolers, power supply units (PSUs), and automotive radiator parts.

| Key Advantages Driving Its Versatility

- Lightweight yet Strong: Ideal for applications where weight reduction is critical (e.g., aerospace, automotive).

- Corrosion Resistance: Suitable for harsh environments (e.g., marine, outdoor).

- Ease of Machining: Can be easily drilled, cut, welded, or formed into complex shapes.

- Cost-Effective: Balances performance and affordability compared to other alloys.