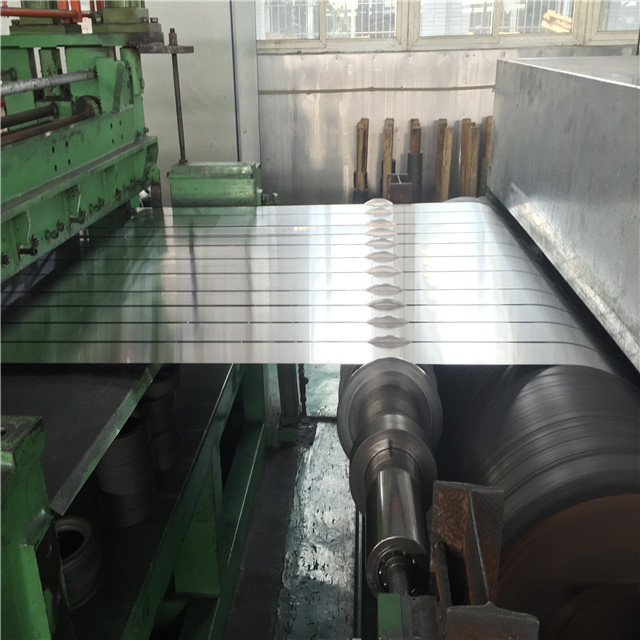

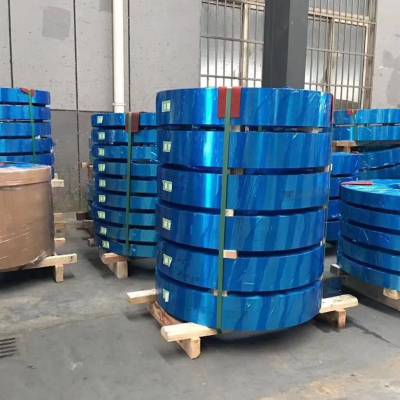

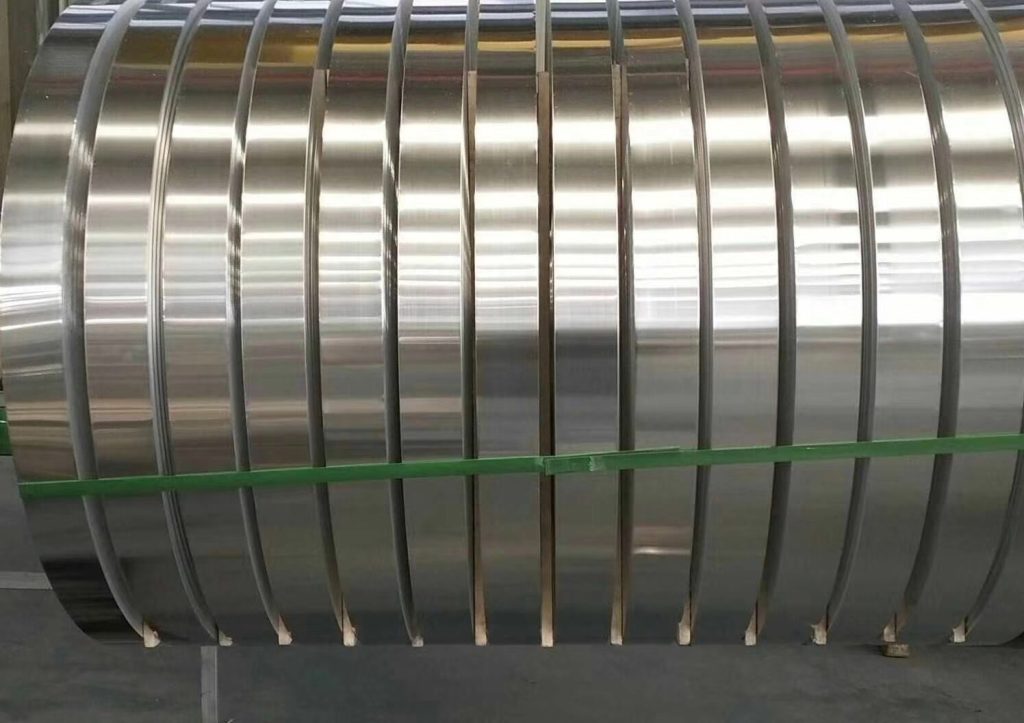

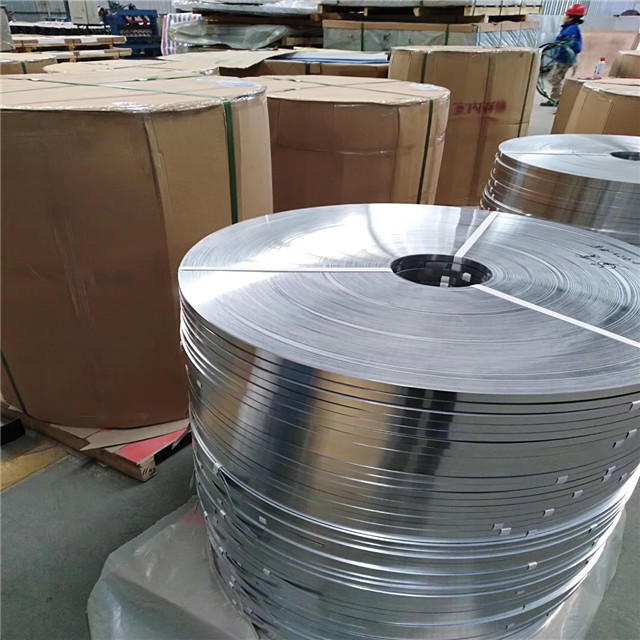

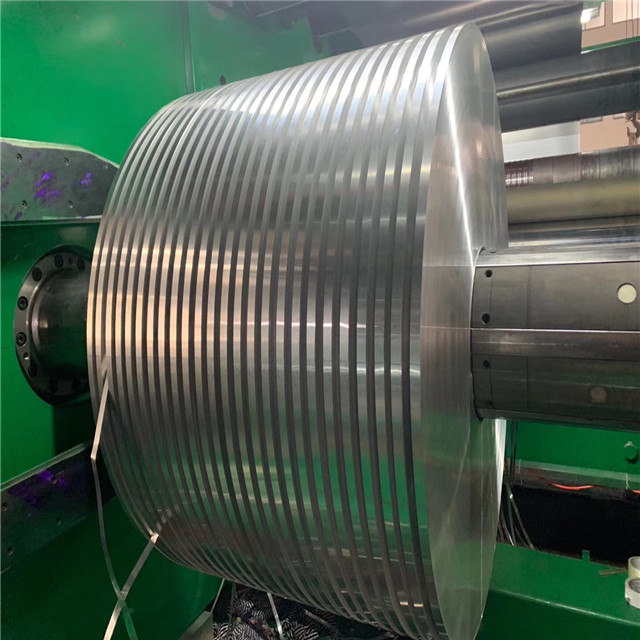

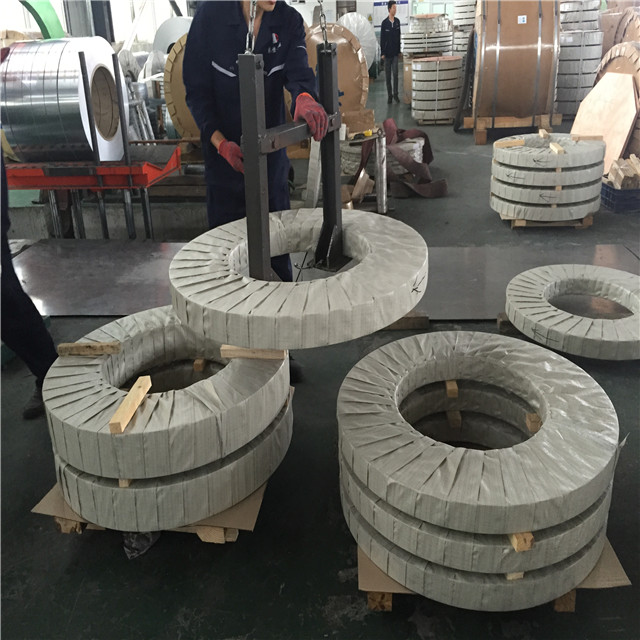

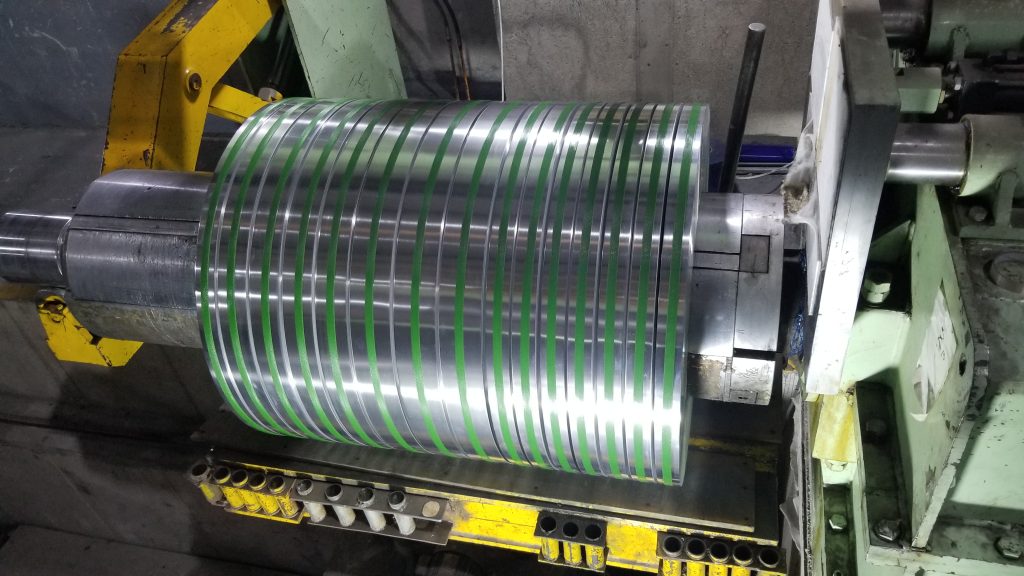

Aluminum Strip

1050 Aluminum Strip

Description | Product Parameters Brand DongChong Place of Origin Chongqing,…

1060 Aluminum Strip

Description | Product Parameters Brand DongChong Place of Origin Chongqing,…

1070 Aluminum Strip

Description | Product Parameters Brand DongChong Place of Origin Chongqing,…

1100 Aluminum Strip

Description | Product Parameters Brand DongChong Place of Origin Chongqing,…

3003 Aluminum Strip

Description | Product Parameters Brand DongChong Place of Origin Chongqing,…

3004 Aluminum Strip

Description | Product Parameters Brand DongChong Place of Origin Chongqing,…

5005 Aluminum Strip

Description | Product Parameters Brand DongChong Place of Origin Chongqing,…

5052 Aluminum Strip

Description | Product Parameters Brand DongChong Place of Origin Chongqing,…

8011 Aluminum Strip

Description | Product Parameters Brand DongChong Place of Origin Chongqing,…