6061 T6 Aluminum Square Rod

- Alloy: 6061

- Alloy Grade: Primarily T6 temper for optimal strength

- Side length: 5 mm – 200 mm (0.2” – 8”)

- Production Method: Extruded

- Service: 7/24 work for you any time

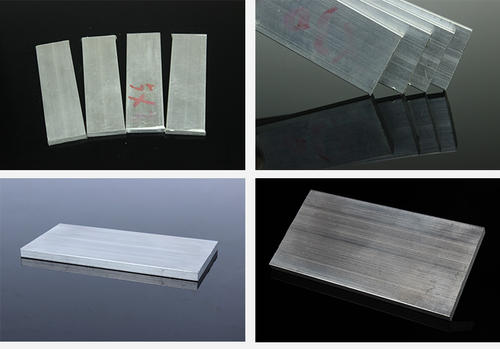

- Packing: Strapping, Plastic bag, Film, Wooden pallet Standard seaworthy export packing or according to customer requirement

- MOQ: 4000kg per size / thickness

- Cutting: Precision-cut to length using saws or CNC machines

- Surface Finishing: Anodizing or powder coating for improved

- Extrusion: Formed using a square die; may undergo heat treatment for enhanced strength.

Description

| Specification of 6061 T6 Aluminum Square Rod

6061 aluminum rod is a versatile and widely used aluminum alloy product, renowned for its excellent balance of strength, corrosion resistance, and workability.

| Product | Aluminum Square Rod |

| Temper | T6 / T651 |

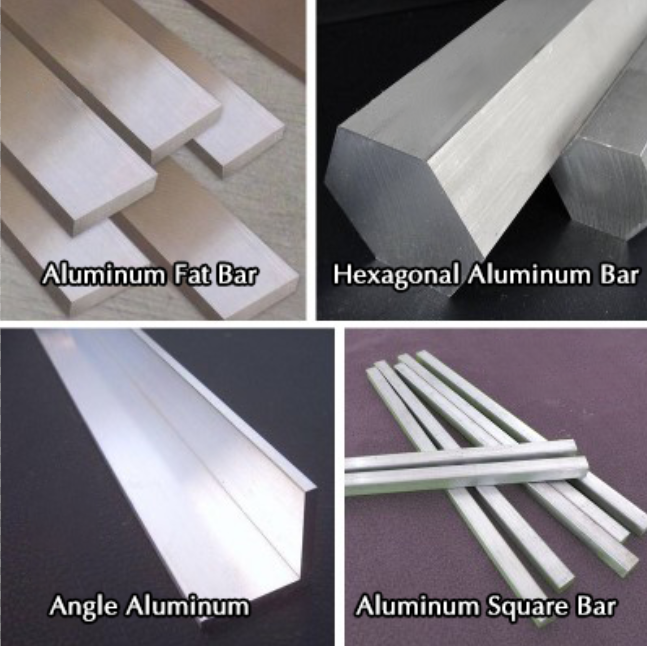

| Types | Square bars, hexagonal bars, angle bars, flat bars |

| Side Length | 5 mm to 200 mm (0.2” to 8”). |

| Custom Sizes | Available for specific structural needs. |

| Common Standards | ASTM B221 (USA), EN 755-3 (Europe), JIS H4140 (Japan) |

| Side Length Tolerance | ±0.1 mm to ±0.3 mm (depending on size). |

| Straightness | ≤ 0.5 mm/m (improved via post-extrusion processing) |

| Packing | Strapping, Plastic bag, Film, Wooden pallet Standard seaworthy export packing or according to customer requirement |

| Payment | T/T, L/C 100% at sight |

| MOQ | 4000kg per size / thickness |

| Delivery time | 1-3 days for spot goods, 10-15 days for normal size,15-25 days for special size. |

| Application | Construction, Shipbuilding, Decoration, Industry, Manufacturing, Machinery, Hardware and other fields |

| Other Types

| Chemical Composition of 6061 Aluminum Rod

6061 aluminum rod primarily consists of aluminum, with key alloying elements including magnesium (Mg) and silicon (Si). The typical chemical composition is as follows:

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al |

| 6061 | 0.40~0.8 | ≤0.7 | 0.15~0.40 | ≤0.15 | 0.8~1.2 | 0.04~0.35 | ≤0.25 | ≤0.15 | ≤0.15 | 97.8 – 98.8% |

| Physical Properties of 6061 Aluminum Rod

| Property | Value Range | Applications |

| Density | ~2.7 g/cm³ | Aerospace and automotive industries where weight reduction is crucial. |

| Melting Point | 582 – 652 °C | Casting and forming processes. |

| Thermal Conductivity | 167 – 188 W/(m·K) | Heat sinks and applications requiring efficient heat dissipation. |

| Mechanical Properties of 6061 Aluminum Rod

| Property | Value Range | Description |

| Tensile Strength | ≥ 290 MPa | High strength suitable for structural applications. |

| Yield Strength | ≥ 240 MPa | Good resistance to deformation under load. |

| Elongation | 8 – 12% | Good ductility and ability to withstand plastic deformation without cracking. |

| Hardness | 65 – 95 HRB | Good level of wear resistance. |

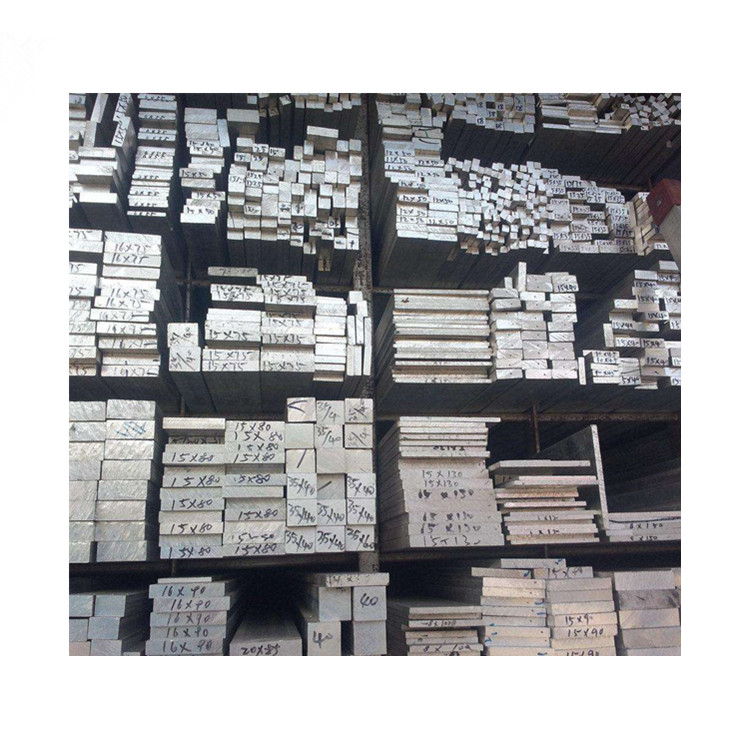

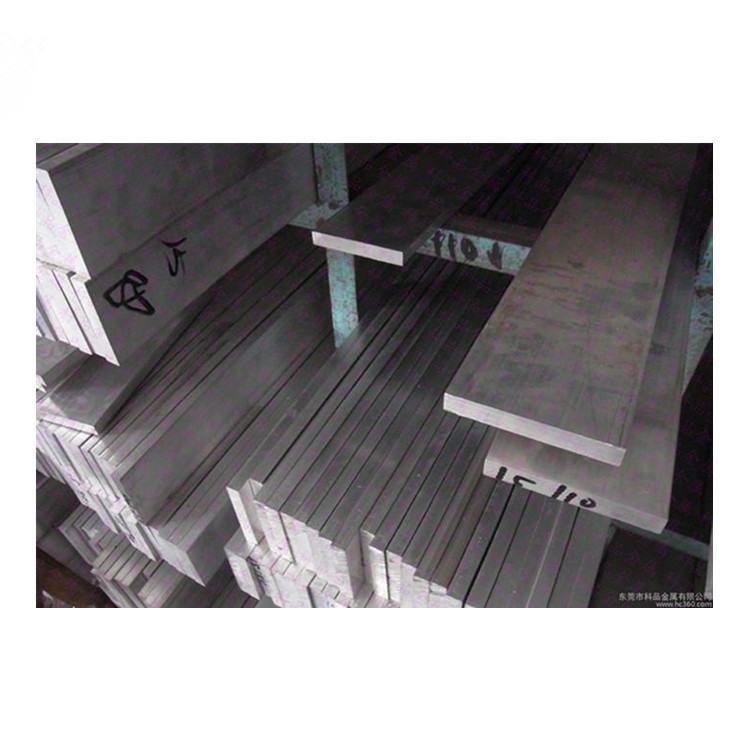

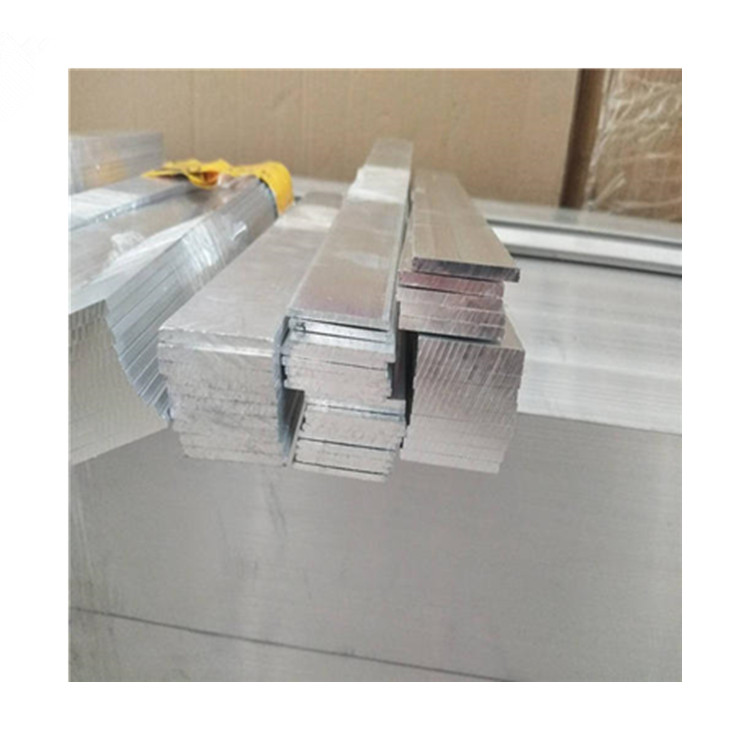

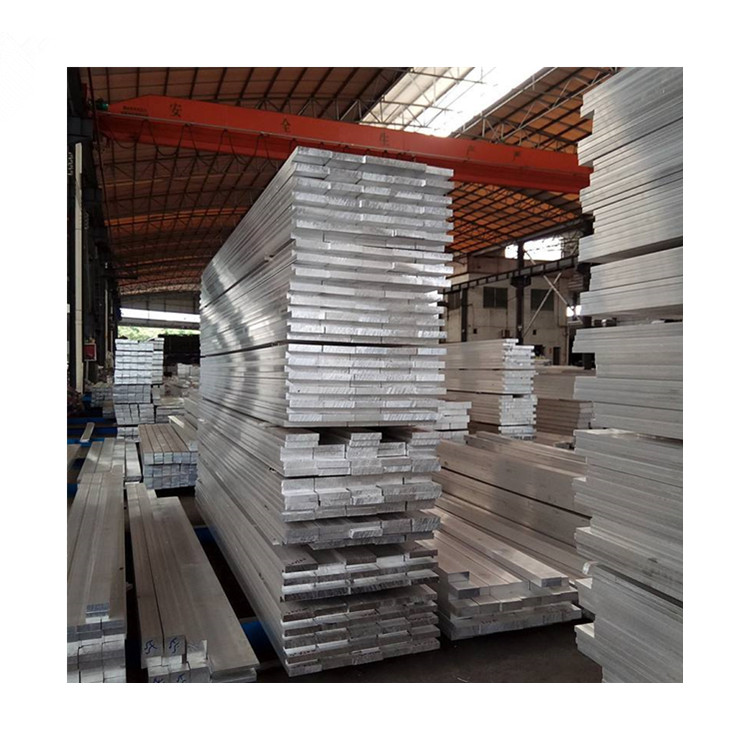

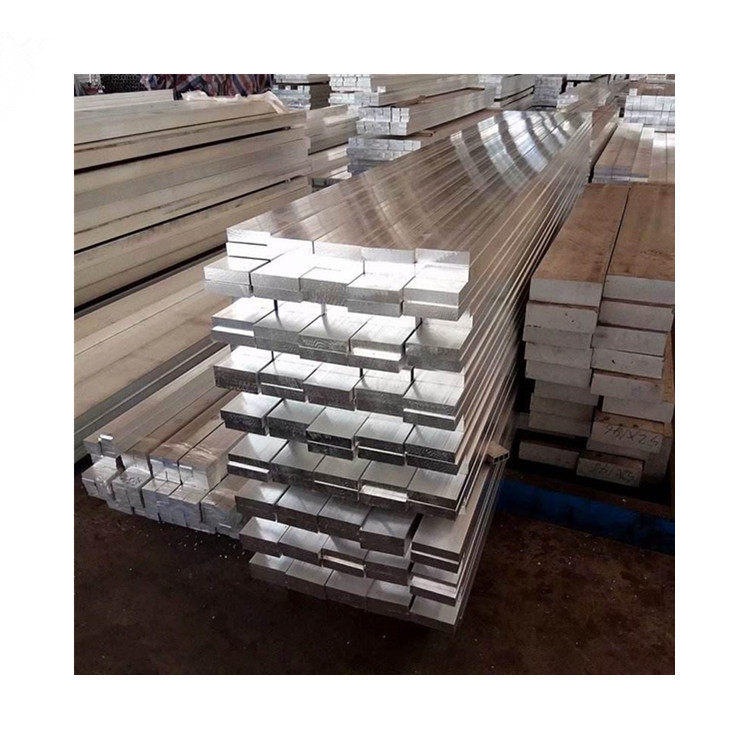

| Warehouse Display

| Applications

6061 aluminum rods are highly versatile and widely utilized across diverse industries due to their exceptional balance of lightweight, strength, corrosion resistance, and machinability. Below are their key application fields:

Construction and Architecture

- Use Cases: Structural supports, beams, columns, and framework for buildings or bridges. Also, curtain walls, window frames, and door systems.

- Why It’s Ideal: High strength-to-weight ratio provides robust structural support without excessive weight. Corrosion resistance ensures longevity, especially in harsh weather conditions. Easy to fabricate and weld, enabling complex architectural designs.

- Typical Products: Beam sections, column segments, bridge framework components, and architectural cladding systems.

Industrial Fabrication

- Use Cases: Machine bases, brackets, structural components for conveyors, robotics, and automated systems.

- Why It’s Ideal: Combines high strength with low weight, ensuring durability and stability for machinery and equipment. Excellent machinability and weldability make it easy to fabricate into complex shapes and integrate into industrial systems.

- Typical Products: Conveyor framework sections, robotic arm components, automation system support structures, and machinery mounting brackets.

Transportation

- Use Cases: Truck/trailer frames, railway car components, agricultural equipment structures.

- Why It’s Ideal: The high strength and lightweight properties of aluminum make it perfect for transportation applications where weight reduction is crucial for improving fuel efficiency and increasing payload capacity. The corrosion resistance of aluminum also ensures the longevity of these components in harsh environments.

- Typical Products: Aluminum truck frames, railway underframes, agricultural machinery structures, and trailer suspension components.

DIY and Prototyping

- Use Cases: Custom fixtures, furniture legs, artistic sculptures.

- Why It’s Ideal: Aluminum’s versatility and ease of machining make it ideal for DIY projects and prototyping. Its lightweight and durable properties allow for creative flexibility. The material can be easily cut, drilled, and shaped without requiring specialized equipment.

- Typical Products: Custom-made clamps, artistic sculptures, DIY furniture legs, and prototype components for various projects.

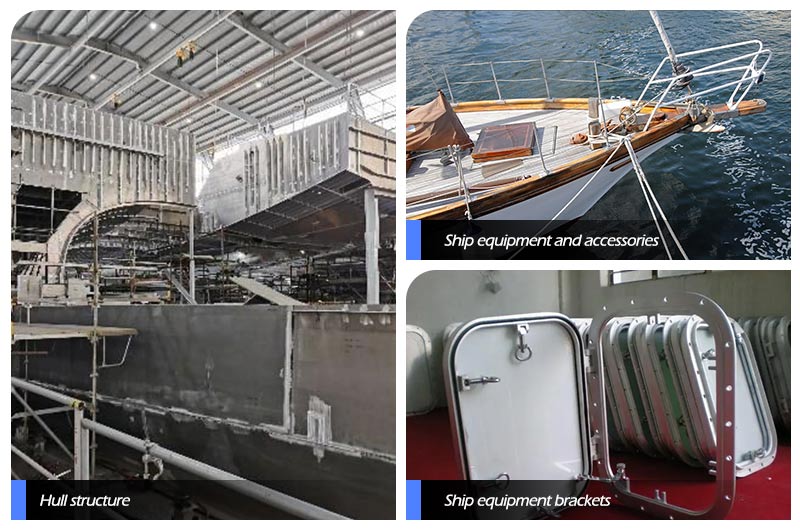

Marine Industry

- Use Cases: Boat hull components, deck fittings, propeller shafts, marine hardware (e.g., hinges, brackets), and offshore structural parts.

- Why It’s Ideal: Excellent corrosion resistance to saltwater ensures durability in marine environments. Lightweight design also enhances boat speed and fuel efficiency.

- Typical Products: Yacht components, fishing boat structures, and underwater equipment parts.

| Key Advantages Driving Its Versatility

- Lightweight yet Strong: Ideal for applications where weight reduction is critical (e.g., aerospace, automotive).

- Corrosion Resistance: Suitable for harsh environments (e.g., marine, outdoor).

- Ease of Machining: Can be easily drilled, cut, welded, or formed into complex shapes.

- Cost-Effective: Balances performance and affordability compared to other alloys.