| Company introduction

Chongqing Dongchong Aluminum Co., Ltd. was founded in 2002 and is located in the Aluminum Industrial Park of Xipeng Town, Jiulongpo District, Chongqing, the “Aluminum Capital of China”. Since its establishment, the company has been adhering to the business tenet of “quality first”, “integrity-based” and “service first”, relying on the strong technology and production capacity of Southwest Aluminum Group, specializing in the research and development, production and material distribution and sales of various aluminum alloys. and deep processing of aluminum products, aluminum product parts processing and other businesses.

The company’s products include aluminum alloy plates, strips, foils, coils, pipes, rods, shapes, coated aluminum coils, curtain wall panels, decorative panels, corrugated panels, profiled panels, roof panels, thermal insulation aluminum coils, etc., which are widely used in military industry, aerospace, electronics, electrical, machinery, chemicals, ships, transportation, automobile ,building materials and decoration. The company integrates scientific research, production, trade, and sheet, strip, and foil cutting and distribution services. The products are exported to all parts of the country and overseas countries.

Our company is equipped with domestic advanced aluminum coil flattening machine, slitting slitting machine, aluminum foil slitting machine, CNC processing equipment, anodizing equipment, embossing machine, engraving machine, laser cutting machine, etc. At that time, we can provide you with a full range of aluminum processing products and services.

In order to better meet customer needs, our company relies on the processing advantages of the company’s cutting and distribution processing center to extend the products to the cutting and distribution business of steel coils/plates. Steel coils/sheets mainly include SGCC/SECC/SPCC and KU400 and other commonly used materials in the electronics and home appliance industries.

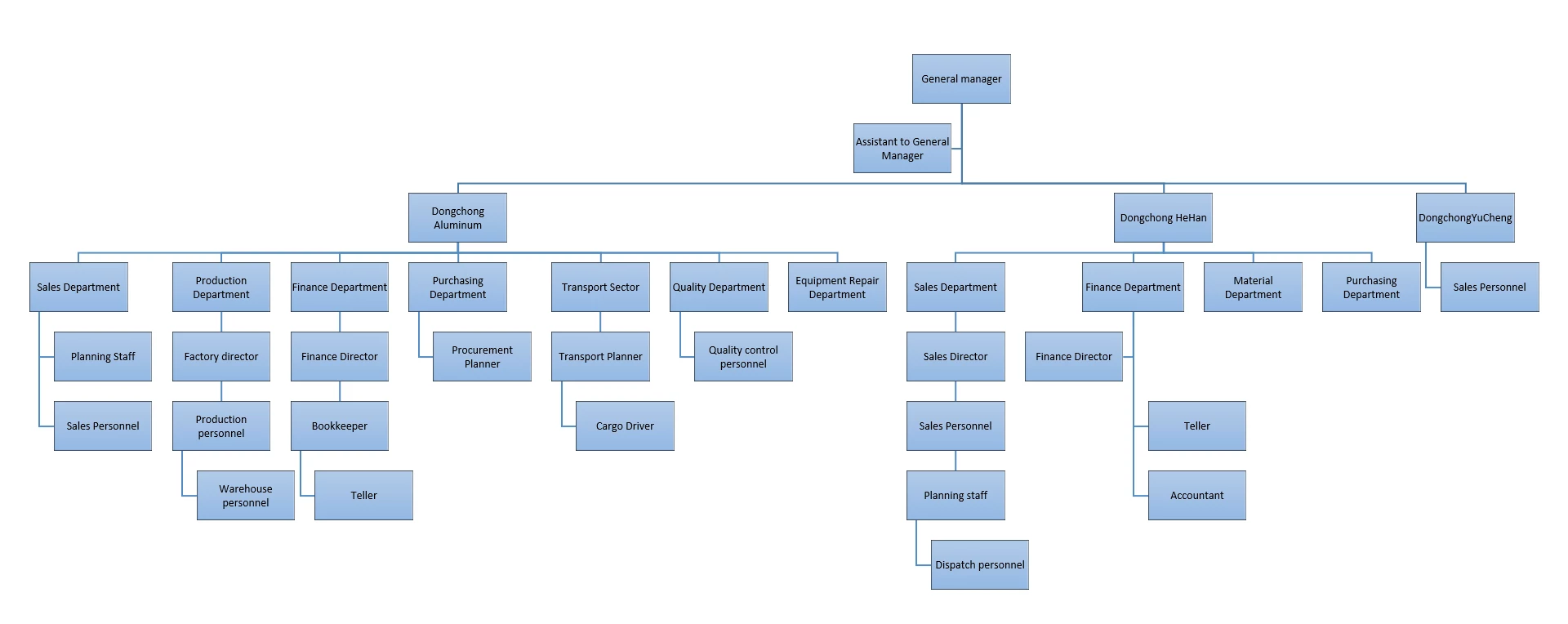

| Company Framework

| Whole Quality Control System

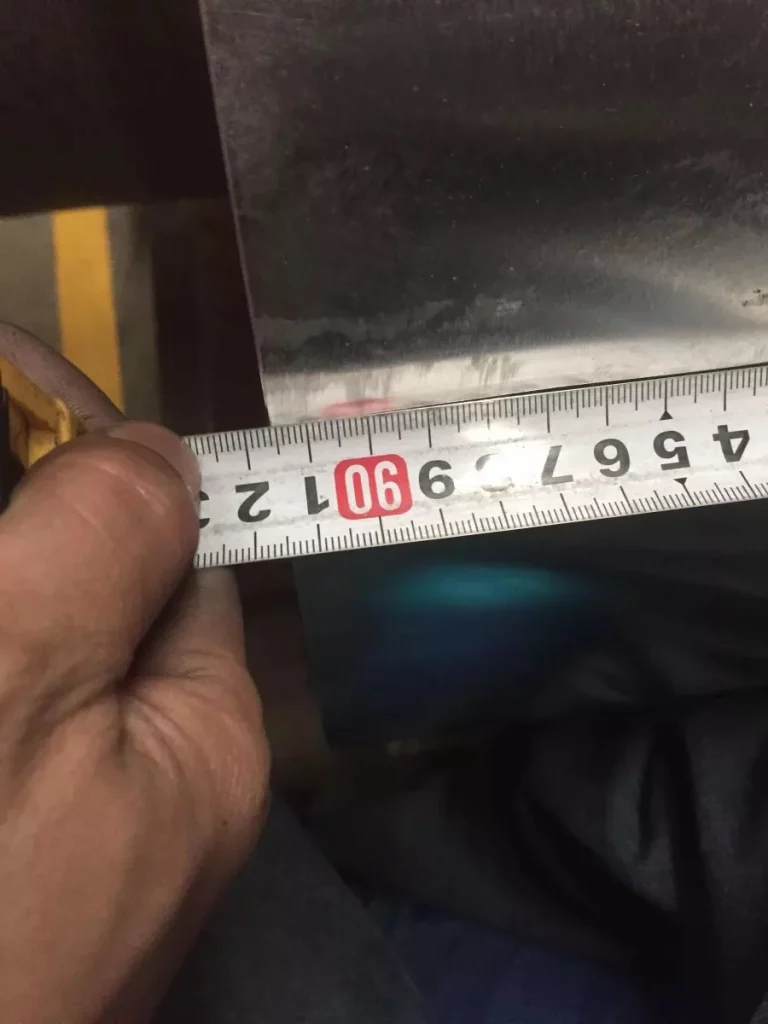

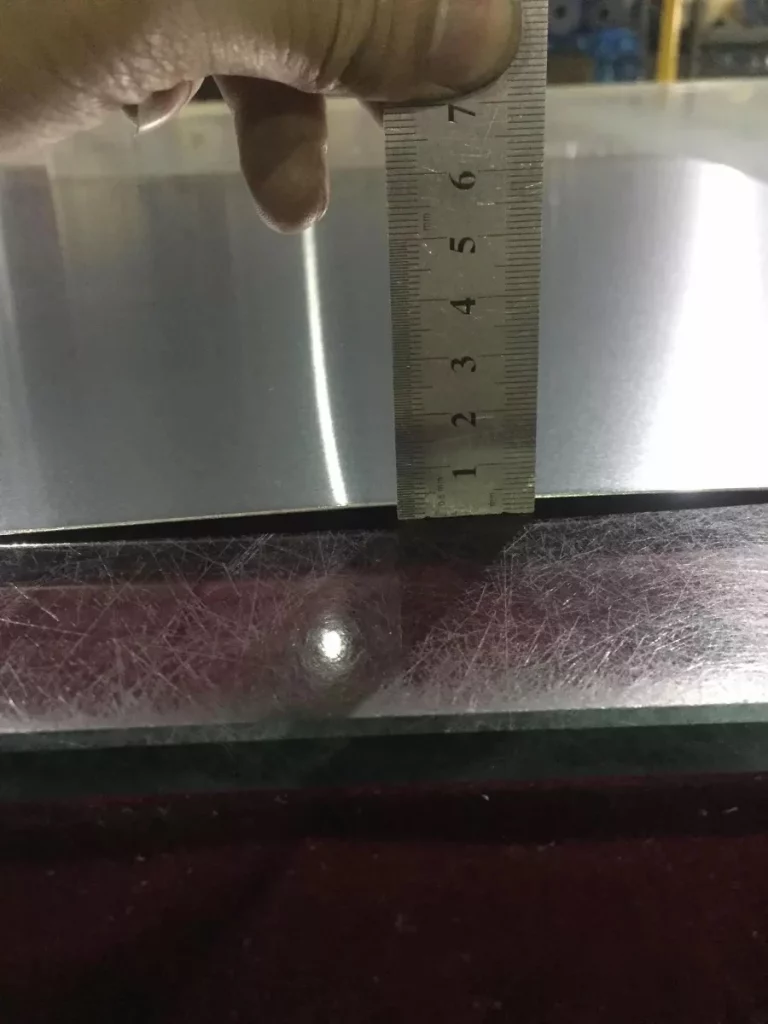

(1) Raw material Warehousing Inspection

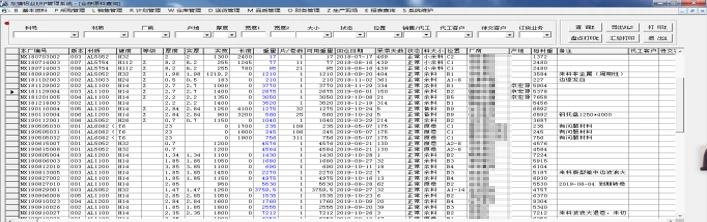

(2) Register into factory ERP system

(3) Production and quality inspection

(4) Final product Area and package style

Finished product Area

Finished product Area Wooden pallet

Wooden pallet Wooden box

Wooden box

(5) Finished goods delivery

Scan product code on label

Scan product code on label Weigh and recheck

Weigh and recheck Deliver

Deliver

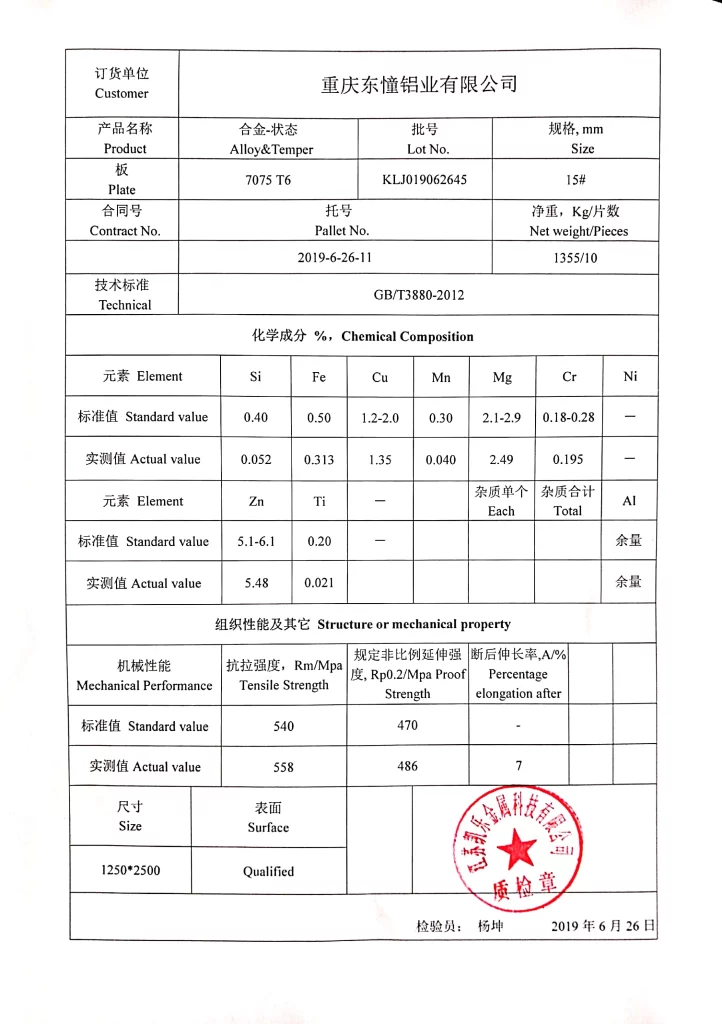

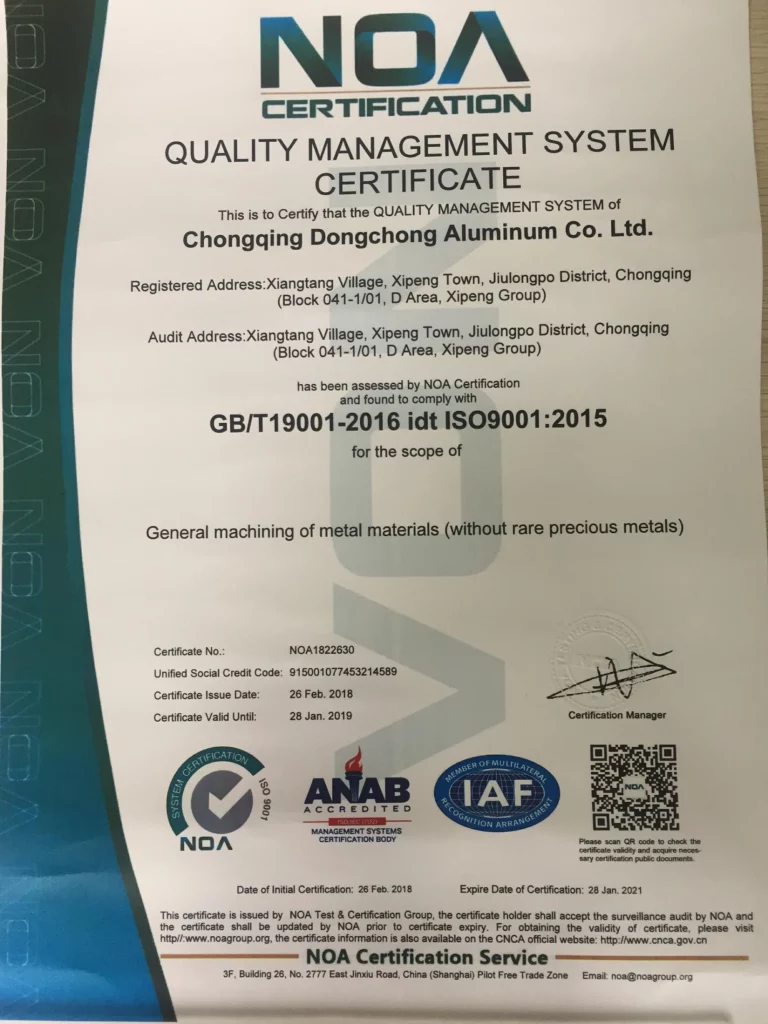

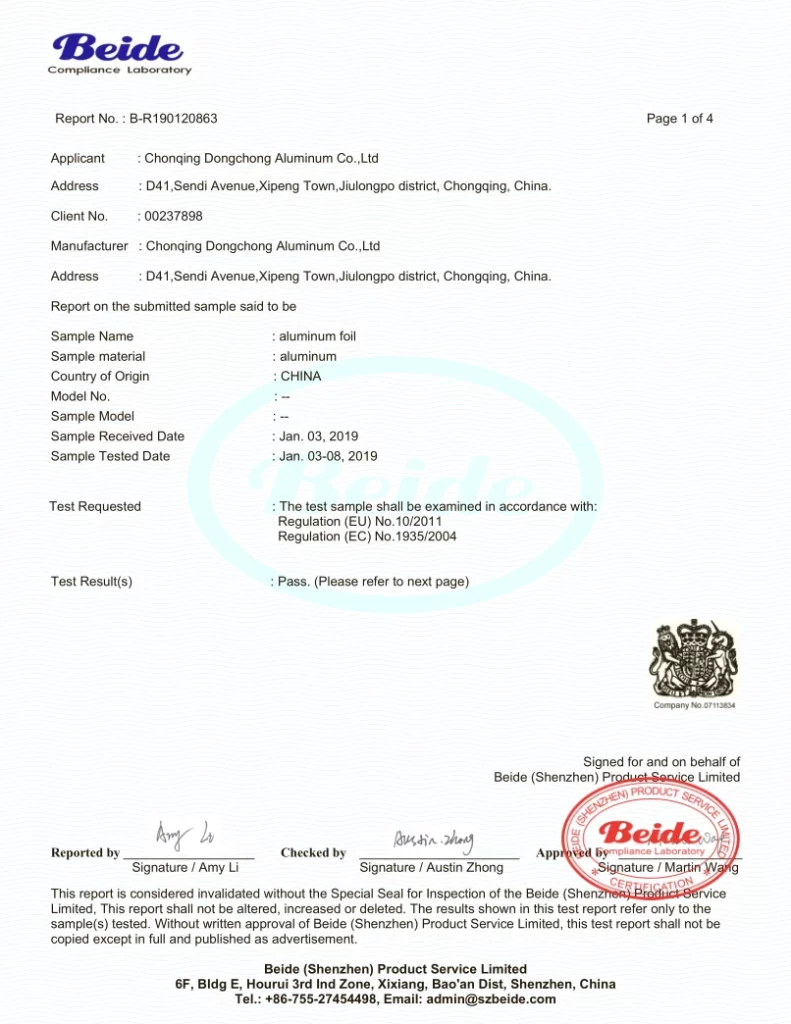

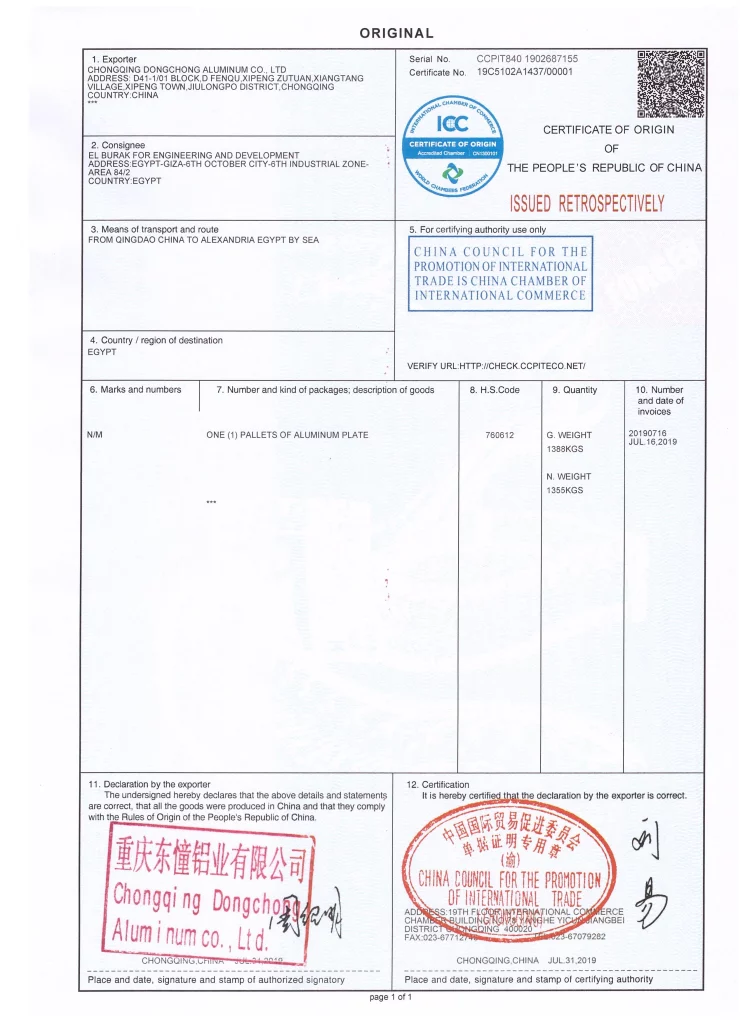

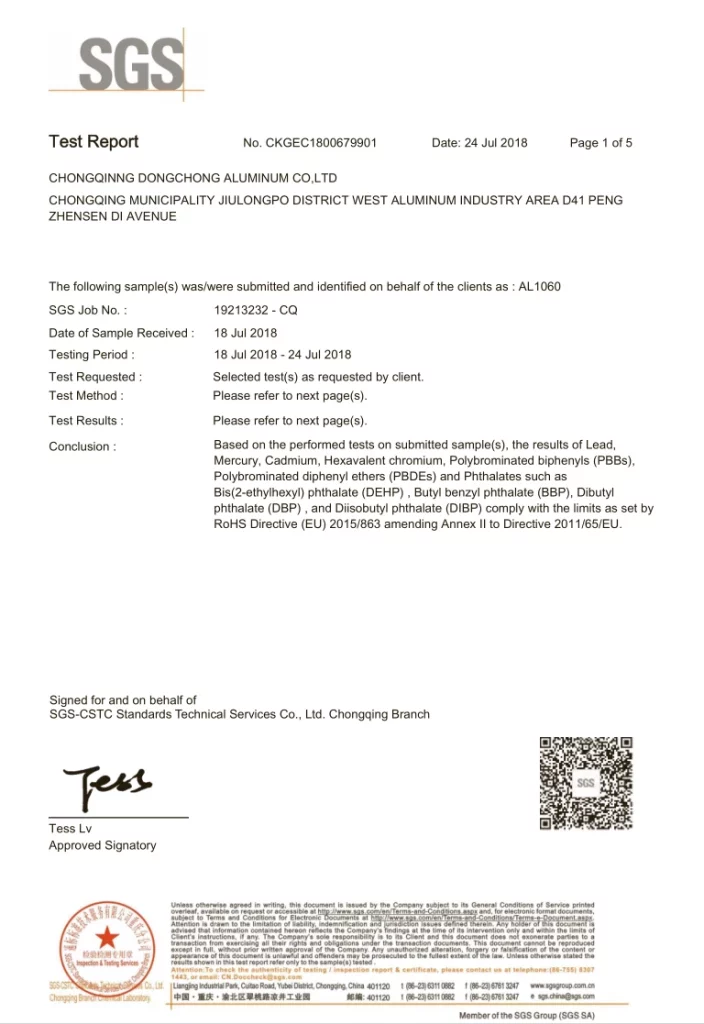

(6) Certificate

(7) Loading into container

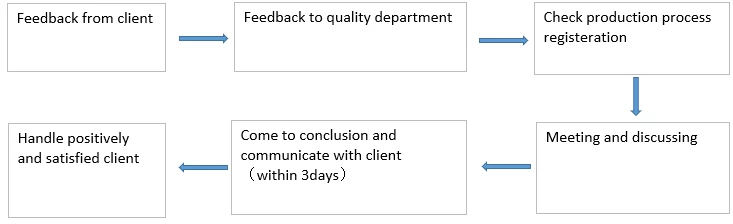

(8) After-sale managment