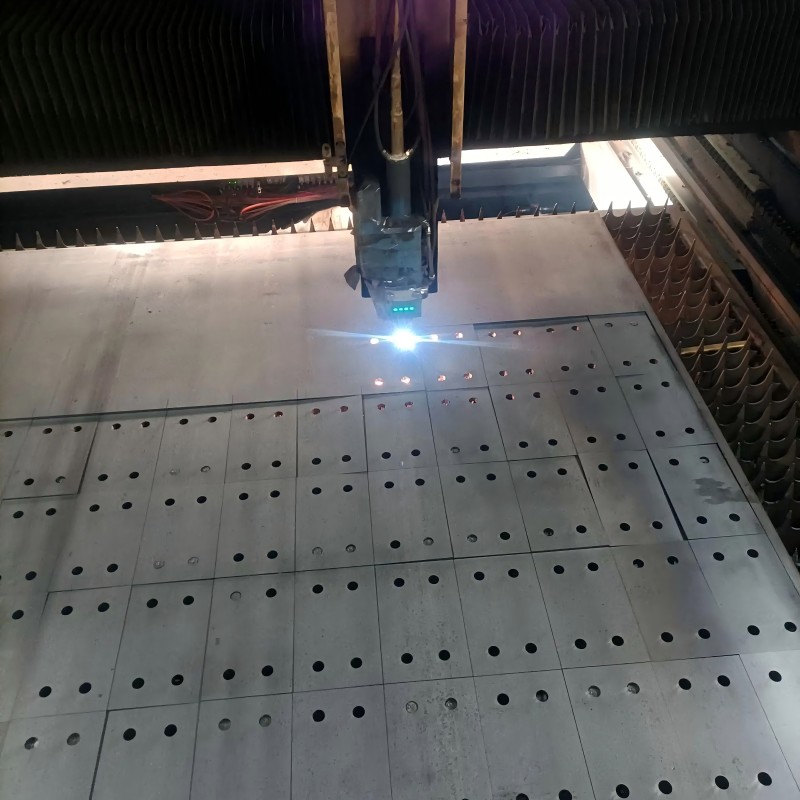

Laser Cutting Aluminum Plate

Laser cutting of aluminum plate is a high-precision, non-contact machining process that uses a laser beam to cut the material. This technology is valued for its ability to produce clean, burr-free edges and its versatility in handling a wide range of material thicknesses and complex designs.

1050 Laser Cutting Aluminum Plate

Description | Specifications Product Aluminum Plate Alloy 1050 Technology Laser…

1060 Laser Cutting Aluminum Plate

Description | Specifications Product Aluminum Plate Alloy 1060 Technology Laser…

1100 Laser Cutting Aluminum Plate

Description | Specifications Product Aluminum Plate Alloy 1050 Technology Laser…

3003 Laser Cutting Aluminum Plate

Description | Specifications Product Aluminum Plate Alloy 3003 Technology Laser…

5005 Laser Cutting Aluminum Plate

Description | Specifications Product Aluminum Plate Alloy 5005 Technology Laser…

5052 Laser Cutting Aluminum Plate

Description | Specifications Product Aluminum Plate Alloy 5052 Technology Laser…

6061 Laser Cutting Aluminum Plate

Description | Specifications Product Aluminum Plate Alloy 6061 Technology Laser…

7075 Laser Cutting Aluminum Plate

Description | Specifications Product Aluminum Plate Alloy 7075 Technology Laser…