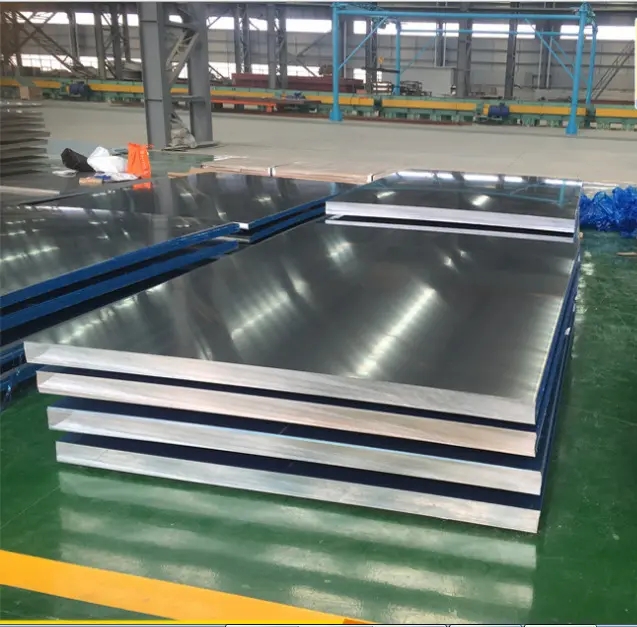

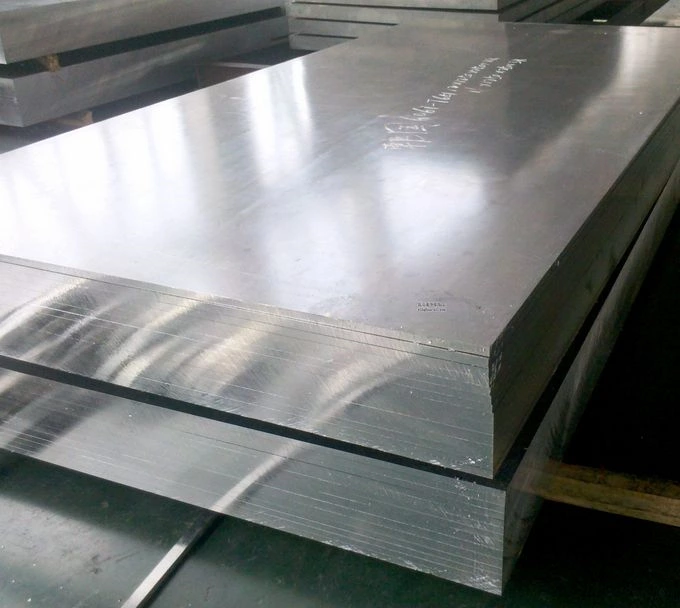

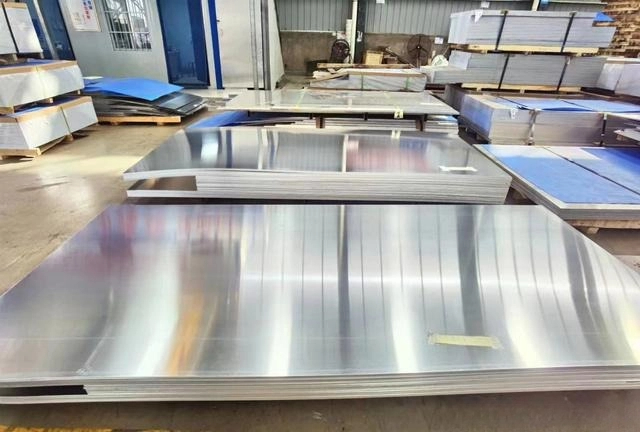

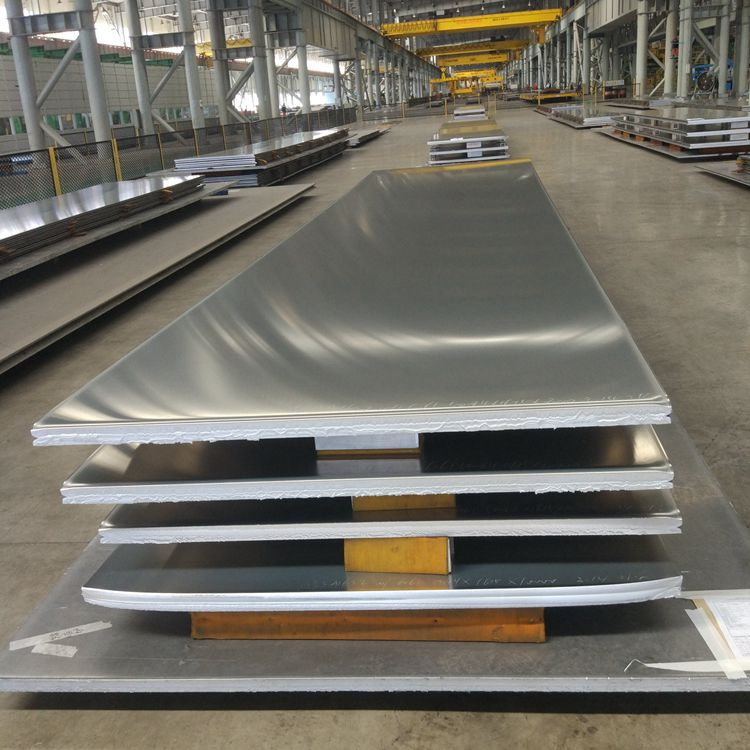

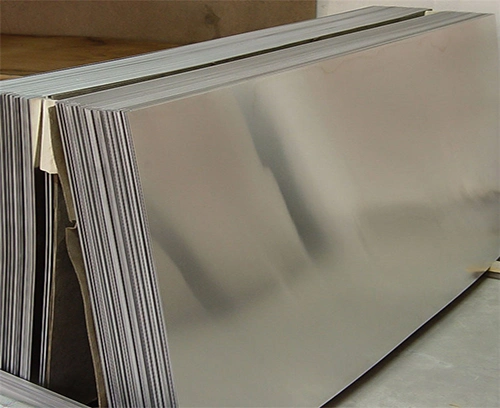

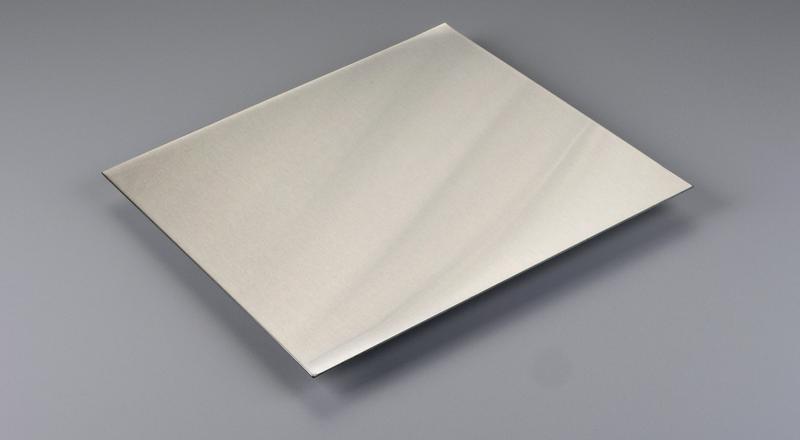

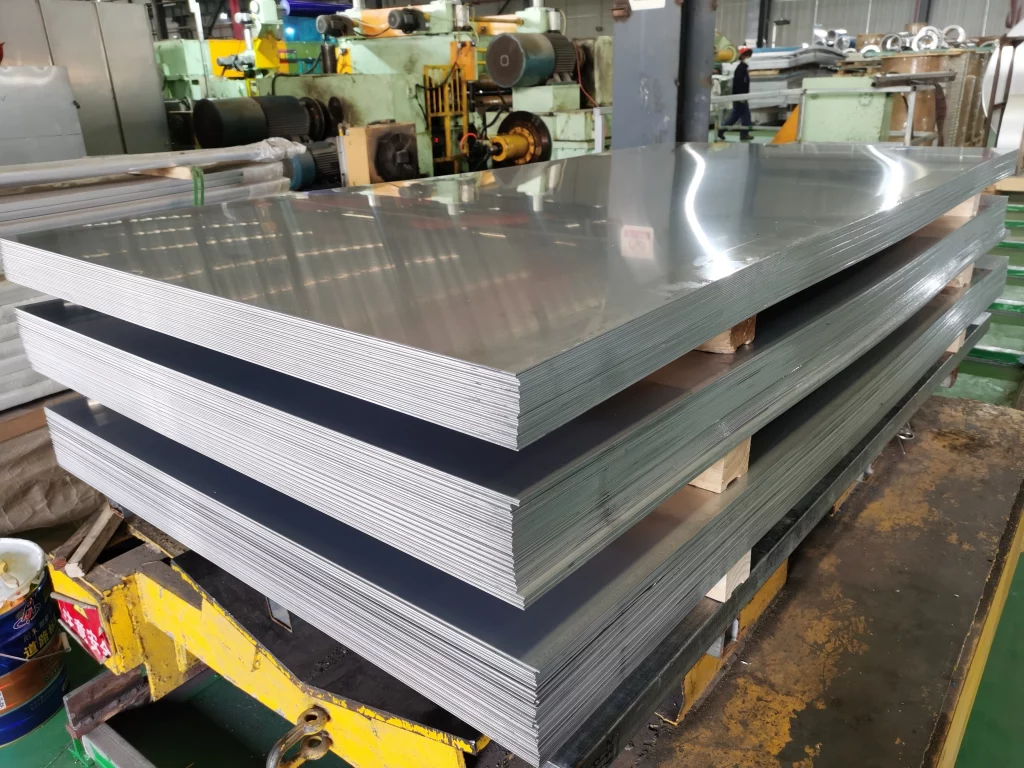

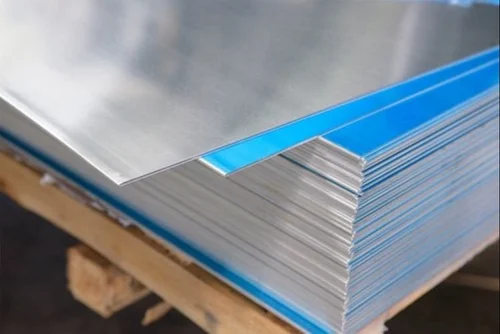

Mill Finish Aluminum Plate

Mill finish aluminum is the term used to describe aluminum that has not been subjected to any secondary surface treatments or coatings after being produced and rolled at the mill. It retains the natural surface characteristics it had upon leaving the manufacturing process.

1050 Aluminum Plate

Description 1050 aluminum plate is a premium choice for applications…

1060 Aluminum Plate

Description With a composition of 99.60% aluminum and 0.05% copper,…

1100 Aluminum Plate

Description 1100 aluminum plate is a commercially pure aluminum alloy…

1070 Aluminum Plate

Description 1070 aluminum plate is a high purity aluminum alloy…

3003 Aluminum Plate

Description 3003 aluminum plate is a versatile alloy in the…

3004 Aluminum Plate

Description 3004 aluminum plate is a versatile alloy known for…

3105 Aluminum Plate

Description 3105 aluminum plate is known for its excellent deep…

5052 Aluminum Plate

Description 5052 aluminum plate is known for its excellent corrosion…

5754 Aluminum Plate

Description 5754 aluminum plate is a medium-strength alloy known for…

5083 Aluminum Plate

Description 5083 aluminum plate is a non-heat-treatable alloy known for…

6061 Aluminum Plate

Description 6061 aluminum plate is a versatile, heat-treatable alloy known…

6063 Aluminum Plate

Description 6063 aluminum plate is a versatile material known for…