6062 Colored Aluminum Coil

- Alloy: 1050, 1060, 1100, 1070, 3003, 3004, 3105, 5052, 5054, 5083, 6061, 6063, 6062, 7075, 8011

- Temper: H12, H14, H16, H24, H26, H32, O, H112, T3, T6, T4, T651,etc.

- Surface: Mill finish, color coated, embossed, engraving, checkered

- Thickness: 0.1-6mm

- Width: 10-2600mm

- Inner core: 76/150/405/505mm

- MOQ: 300-500 KG

Description

Color coated aluminum coils, processed through cleaning, chrome plating, roller coating, and baking, feature a variety of painted surfaces. Known for their lightweight, vivid colors, ease of processing, and rust resistance, these coils are extensively used in insulation boards, curtain walls, roofing systems, ceilings, and more. The surface paint is categorized into polyester and fluorocarbon types, with options for single, double, or triple coats varying in thickness from 4-20 μm for singles, 25-28 μm for doubles, and 35-38 μm for triples. The coils also offer a range of surface patterns.

| Specifications of 6062 Colored Aluminum Coil

| Place of Origin | Chongqing, China |

| Brand | DongChong |

| Certificate | API, BIS, ISO9001 |

| Thickness | 0.1-6mm |

| Width | 10-2600mm |

| Inner core | 76/150/405/505mm |

| Packing | Standard export packaging options include wooden boxes, or as specified |

| Payment | T/T, L/C 100% at sight, Western Union |

| Supply Ability | 50000T/per Month |

| MOQ | Normally 5 tons, special require need discuss |

| Delivery time | 1-3 days for spot goods, 10-15 days for normal size, 15-25 days for special size |

| Application | Roofing, ceiling, cladding, gutter, facade wall |

| Chemical Composition of Colored Aluminum Coil (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | 0thers: | Al: Min. | |

| Each | Total | ||||||||||

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | – | 0.05 | 0.03 | 0.03 | – | 99.50 |

| 1060 | 0.24 | 0.35 | 0.05 | 0.03 | 0.03 | – | 0.05 | 0.03 | 0.03 | – | 99.60 |

| 1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | – | – | 0.04 | 0.03 | – | 99.70 |

| 1100 | 0.95 Si+Fe | 0.05~0.20 | 0.05 | – | – | 0.10 | – | 0.05 | 0.15 | 99.00 | |

| 3003 | 0.60 | 0.70 | 0.05~0.20 | 1.0~1.5 | – | – | 0.10 | – | 0.05 | 0.15 | remainder |

| 3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | – | 0.25 | – | 0.05 | 0.15 | remainder |

| 3105 | 0.60 | 0.70 | 0.30 | 0.3~0.8 | 0.2~0.8 | 0.20 | 0.40 | 0.10 | 0.05 | 0.15 | remainder |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2~2.8 | 0.15~0.35 | 0.10 | – | 0.05 | 0.15 | remainder |

| 5754 | 0.10~ 0.35 | 0.30~ 0.50 | 0.10~ 0.30 | 0.15~ 0.50 | 3.8~ 4.9 | 0.10~ 0.30 | 0.10 | 0.05 | 0.15 | 0.15 | remainder |

| 5083 | 0.10~ 0.60 | 0.10~ 0.70 | 0.10~ 0.50 | 0.20~ 0.80 | 4.0~ 4.9 | 0.10~ 0.35 | 0.10 | – | 0.15 | 0.15 | remainder |

| 6061 | 0.4~ 0.8 | 0.15~ 0.40 | 0.15~ 0.40 | 0.10~ 0.35 | 0.8~ 1.2 | 0.04~ 0.35 | 0.10 | – | 0.15 | 0.15 | remainder |

| 6062 | 0.2~ 0.6 | 0.2~ 0.4 | 0.1~ 0.3 | 0.1~ 0.5 | 0.4~ 0.9 | 0.04~ 0.35 | 0.10 | – | 0.15 | 0.15 | remainder |

| 6063 | 0.2~ 0.6 | 0.35~ 0.7 | 0.10~ 0.40 | 0.10~ 0.50 | 0.4~ 0.9 | 0.04~ 0.35 | 0.25 | – | 0.15 | 0.15 | remainder |

| 7075 | 0.15~ 0.40 | 0.20~ 0.40 | 1.2~ 2.0 | 0.15~ 0.50 | 2.1~ 2.9 | 0.15~ 0.35 | 0.15~ 0.35 | – | 0.15 | 0.15 | remainder |

| 8011 | 0.10~ 0.40 | 0.30~ 0.70 | 0.10~ 0.30 | 0.05~ 0.30 | 0.05~ 0.30 | 0.05~ 0.20 | 0.05~ 0.20 | – | 0.15 | 0.15 | remainder |

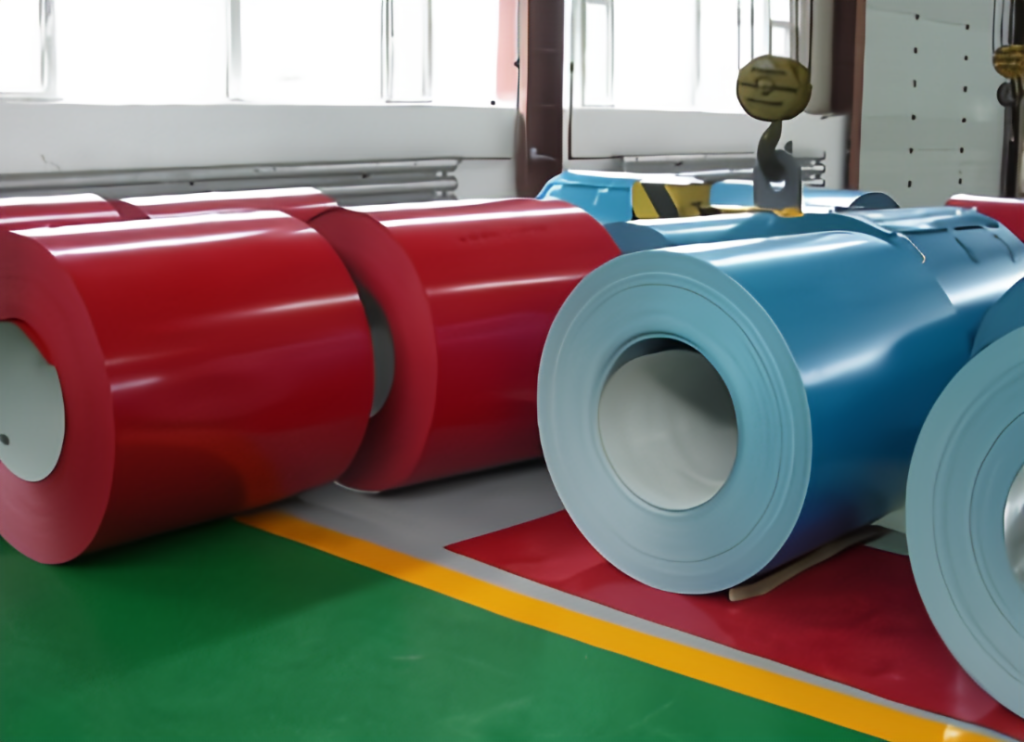

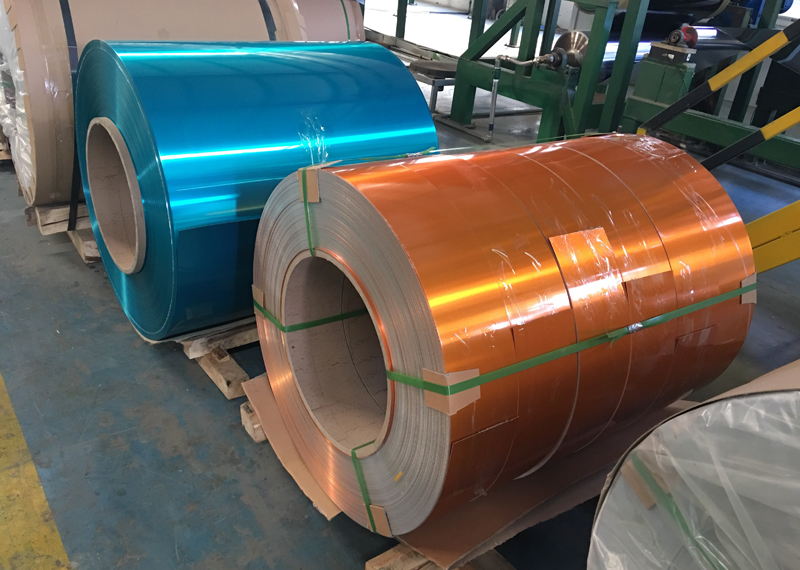

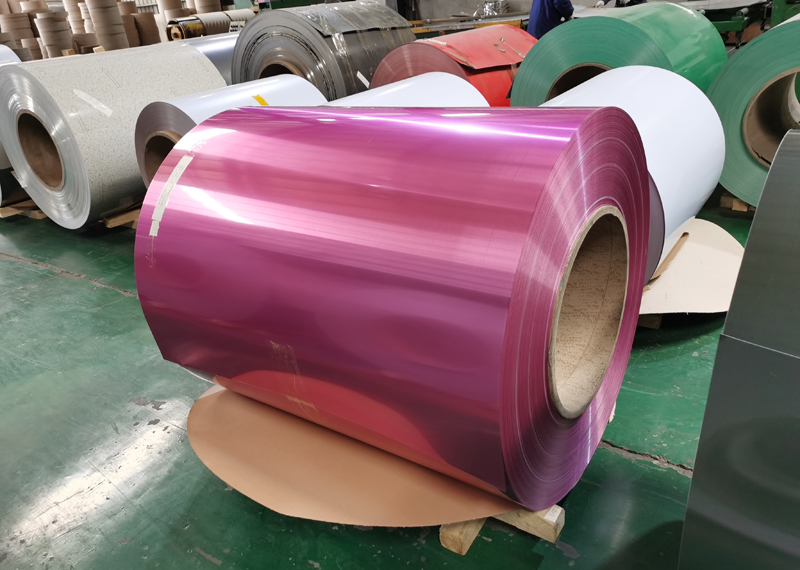

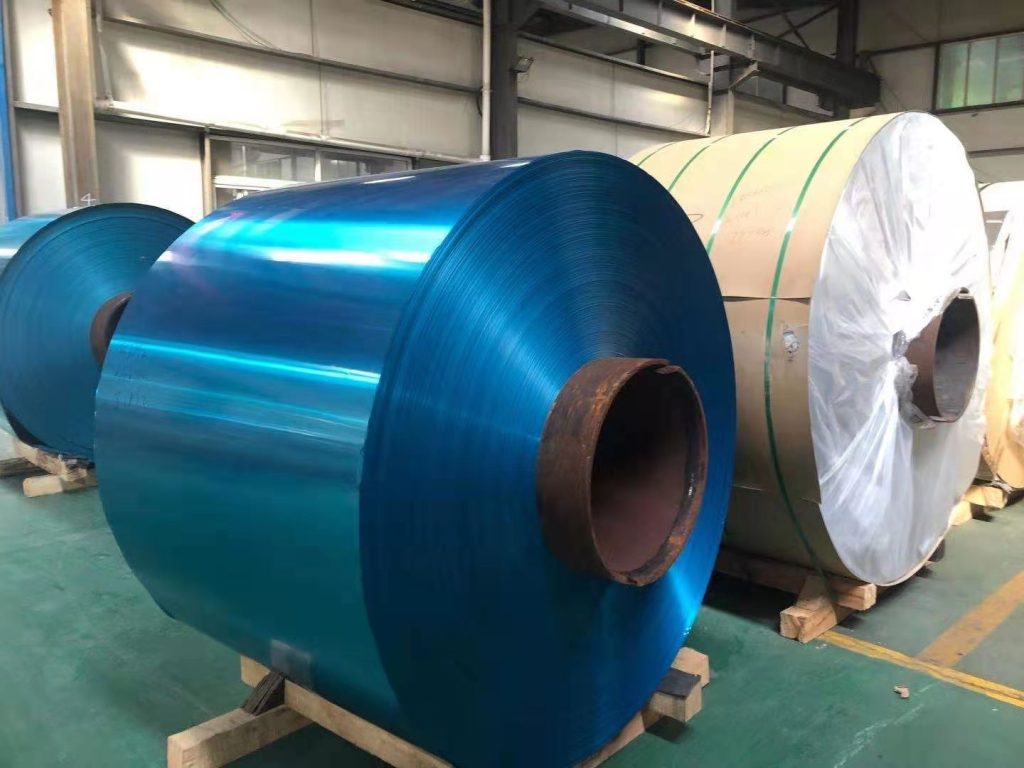

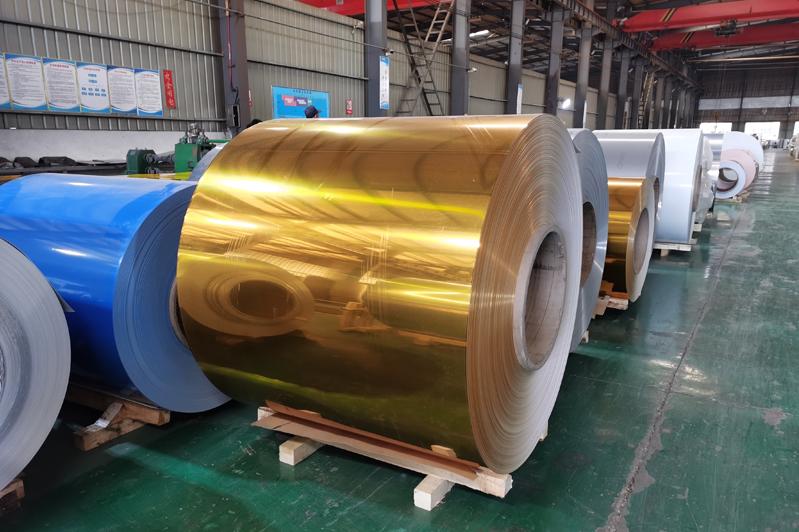

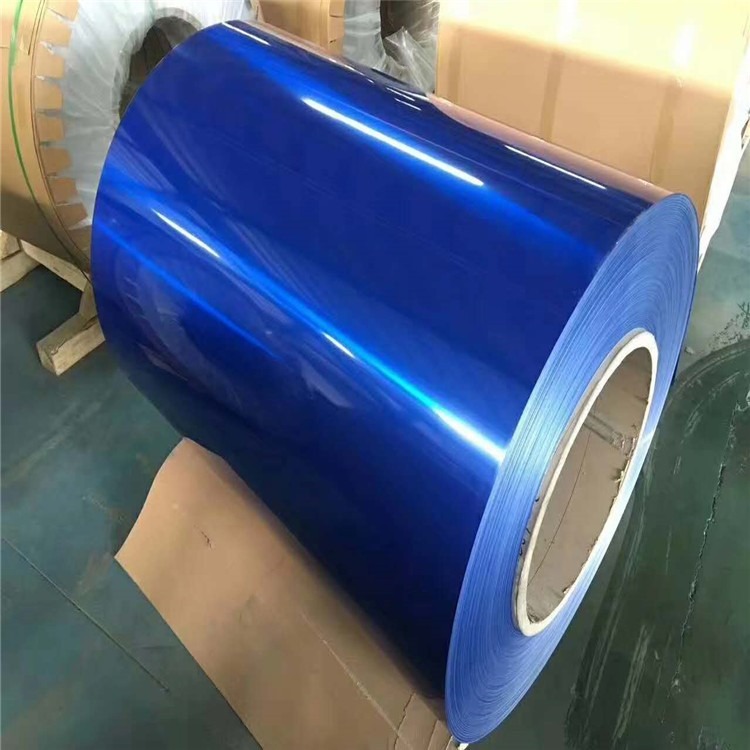

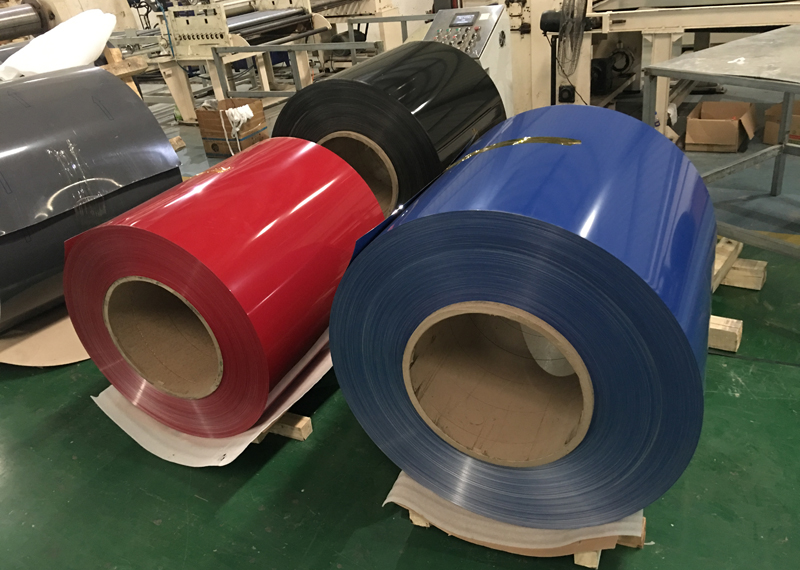

| Product Image

| Advantages of DongChong Aluminum

- Diverse Color Options: Offer a wide range of color choices, including standard color cards and custom colors based on customer requirements, to meet the aesthetic needs of various construction projects.

- Customized Sizes: Produce non-standard sizes of aluminum coils according to specific customer demands, reducing the need for on-site processing and improving material utilization.

- Surface Treatment Options: In addition to basic painting processes, provide different surface treatments such as sandblasting, brushing, and embossing to enhance the appearance and functionality of the products.

- Quick Sampling: Provide samples quickly so that customers can confirm the color and quality before placing orders, reducing communication costs and time.

- Small Batch Customization: Offer customization services even for small batch orders to meet the needs of small-scale projects or experimental orders.

- Professional Design Support: Provide professional design consulting services to help customers choose the aluminum coil specifications and colors most suitable for their project requirements.

- Flexible Production Scheduling: Quickly adjust production lines to accommodate custom orders, ensuring the accuracy and reliability of delivery times.

- Quality Assurance: Ensure that all customized products meet quality standards, providing detailed quality inspection reports and product compliance certificates.

- Customer Customization Cases: Providing past successful customization cases to help customers quickly develop solutions that meet their needs.

- Ongoing After-Sales Service: Provide continuous technical support and customer service to ensure that any issues customers encounter when using customized products are resolved promptly.

| Application Scenarios of Color Aluminum Coils

| Why Choose DongChong Aluminum

- Experience and Expertise: DongChong Aluminum, established in 2002, has decades of experience in the aluminum industry, ensuring a high level of expertise and knowledge in aluminum production and processing.

- Wide Product Range: With a diverse product line that includes aluminum alloy plates, strips, foils and coils, DongChong Aluminum can meet a variety of customer needs.

- Quality Commitment: Adhering to a business philosophy of “quality first” and “integrity-based,” DongChong ensures that all products meet strict quality standards.

- Advanced Equipment: Utilizing state-of-the-art equipment, DongChong’s technology and machinery are among the top in Southwest China, ensuring precision and efficiency in production.

- Customization Services: Offering customization options, DongChong can tailor products to specific customer requirements, from slitting and cutting to surface treatments.

- Large Stock Resources: With a stock of 10,000 tons, DongChong can quickly fulfill orders and meet the needs of different clients without delays.

- Comprehensive Services: Providing a one-stop service that includes research and development, production, material distribution, and sales, DongChong is a single source for all aluminum-related needs.

- Global Reach: Exporting products to various countries, DongChong has a global presence and can cater to international customers.

- Quality Control System: Implementing a whole quality control system from raw material warehousing to after-sales management ensures that every step of the production process is monitored for quality.

- Certifications and Standards: Offering products that meet international standards like ISO, FDA, and others, ensuring reliability and safety.

- Professional Team: Staffed by professionals with extensive experience in the industry, DongChong’s team can provide efficient service and support.

- Innovative Approach: With a commitment to continuous improvement and participation in professional training, DongChong stays at the forefront of aluminum technology and trends.

- Sustainability: As a provider of recyclable aluminum products, DongChong contributes to sustainable practices and environmental responsibility.

| FAQ

Q1. What is the minimum order quantity?

500 kg for regular size color coated aluminum coil. If you have special needs, please contact our experts for consultation.

Q2. What are your payment terms?

Support T/T, L/C 100% at sight, Western Union.

Q3. How is your delivery time?

Usually, it takes 15 to 20 days after receiving the advance payment. The specific delivery time depends on the goods and quantity of the order.

Q4. Will free samples be provided?

Yes, we can provide you with free samples, but the freight needs to be borne by the buyer.

Q5. Why can I trust you and place an order with you?

We are a Chinese aluminum composite panel manufacturer and supplier with more than 22 years of experience. We maintain the fastest delivery speed. Because we have perfect production equipment.

Q6. How can I get the best quotation?

Please provide the Dongchong expert team with the product specifications, purchase quantity, delivery address, contact information and other information you need, and our experts will provide you with one-to-one service.

| Packing and Shipping